Vacuum Feeder

Vacuum Feeder (VF)

Overview

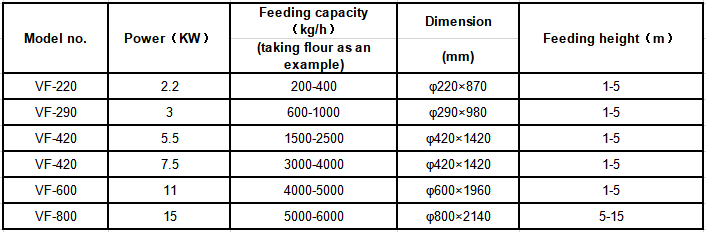

Vacuum feeder is a new product developed on the basis of extensive absorption of similar foreign products, and it is currently an ideal and perfect vacuum conveying equipment for powder, granular, and powder-granular mixtures. It reduces the labor intensity of workers, solves the problems of dust overflow during feeding, and is the preferred equipment for pharmaceutical factories and food factories to pass GMP certification and achieve clean and civilized production. The power is from 2.2KW to 15KW, and the conveying capacity is 0.2-6 tons/hour.

Working Principle of VF

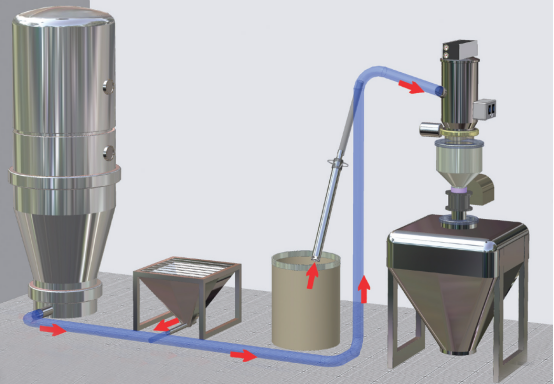

The negative pressure air flow generated by vacuum pump is used to suck the material into the feed port through the suction pipe, and the gas is separated with the material in the vacuum feeder, and the clean air through the filters is discharged into the atmosphere by the vacuum pump, and then the material falls into the silo. When the feeding time arrives, the vacuum valve is closed, and the blanking valve is opened, then the vibrating device that assists the blanking is started, to make the material fall into the designated equipment. When the blanking is over, the back-blowing airbag automatically cleans the filter to make sure the next cycle will be played efficiently.

Features

1. Simple: automatic control, the suction and discharging time can be set at will within 0~99 seconds. Which is simple and convenient;

2. Hygiene: closed transportation, no dust leakage, no cross-contamination, in line with GMP standards, to meet CIP requirements, and can provide aseptic equipment

3. Simple and fast installation;

4. Cleaning: dust-free operation, eliminate dead ends, disassembly, cleaning and material replacement are fast and convenient:

5. Economical: a machine can be used in turn for multiple sets of equipment, high efficiency and energy saving, no need for warm-up and standby, and low operation and maintenance costs.

Applications

Materials for food industry, pharmaceutical industry and chemical industry, such as pharmaceutical powder, Ganoderma lucidum powder, matcha powder, protein powder, milk powder, flavor, fragrance, monosodium glutamate, adsorbent, catalyst, graphite, rouge, blush, polyethylene, polypropylene, polyoxyethylene, etc.

Specifications

Our engineering team can walk you through the design process and help you choose the suitable vacuum feeder(VF) that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms