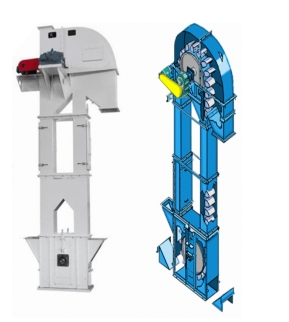

NE Chain-plate Bucket Elevator

NE Chain-plate Bucket Elevator

Overview

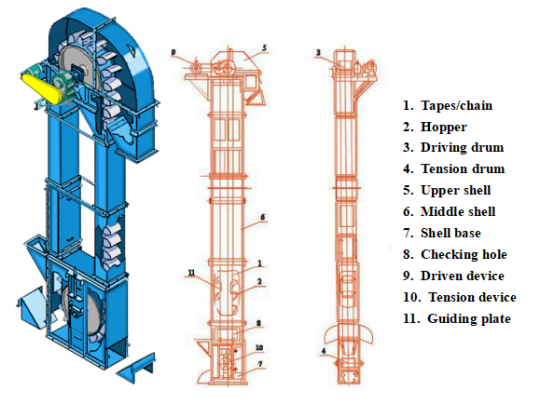

NE type bucket elevator is of chain-plate type, gravity induced discharge lifting equipment. Compared with other lifting, it has the following characteristics: the lifting range is wide, the type, characteristics and lumpiness of the material are not strict, and the abrasive material can be improved, and the material temperature ≤ 250 °C; The conveying capacity is as large as 15-800m3/h, and the lifting capacity range is 800m/h; The driving power is small, the service life is long, the lifting height is high, the operation is stable, the sealing is good, and the operation and maintenance are convenient. This series of bucket elevators adopts advanced design principles to ensure the reliability of the whole machine, structural accuracy, and casing rigidity are better than other bucket elevators. NE type bucket elevator adopts inflow feeding, gravity-induced discharge, and no material return. It is suitable for vertical conveying of powder, granular, small block, abrasive and non-abrasive materials, such as raw meal, cement, coal, limestone, dry clay, clinker, etc.

Features of NE Chain-plate Bucket Elevator

1. Wide range of application. This type of bucket elevator has few requirements for the material type, characteristics and lump size. It can not only improve the general powder, granular and lumpy materials, but also improve the materials with high grindability. The temperature of the material ≤ 250°.

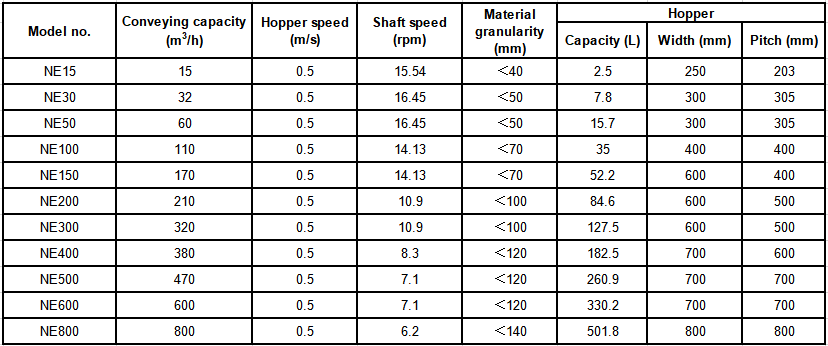

2. Large conveying capacity. This series of bucket elevators have many specifications from NE15~NE800. The lifting capacity ranges from 15~800m3/h.

3. The driving power is small. This type of elevator adopts inflow feeding, gravity-induced discharge, and adopts dense layout transportation of large-capacity hopper , low chain speed and large lifting capacity. When the material is lifted, there is almost no material return and excavation, so the invalid power is less, and the power consumption is 70% of the chain bucket elevator.

4. Long service life. The feeding of the bucket elevator adopts the inflow type, no need to dig the material with a bucket, and the extrusion and collision phenomenon rarely occurs between the materials, the design of this machine ensures that the material will not be sprinkled in feeding, lifting and unloading, which reduces mechanical wear, and the conveyor chain adopts a plate chain type high-strength wear-resistant chain, which greatly prolongs the service life. Under normal use, the service life of the conveyor chain is more than 5 years.

5. High lifting height. This series of bucket elevator has low chain speed, stable operation, and adopts plate chain type high-strength wear-resistant alloy steel chain, so it can reach a high lifting height (height about 40M).

6. Good sealing and less environmental pollution.

7. Good operational reliability. The advanced design principle ensures the reliability of the whole machine, and the trouble-free time exceeds 30,000 hours.

8. Easy to operate and maintain, with few wearing parts.

9. Small mechanical size. Compared with various other bucket elevators with the same lifting capacity, the mechanical size of this bucket elevator is smaller.

10. Strong structural rigidity and high precision. The casing is folded and ribbed in the middle, and then welded, with good rigidity and beautiful appearance.

11. Low cost of operation. Due to energy savings and low maintenance, the operation cost is extremely low.

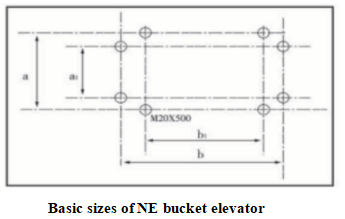

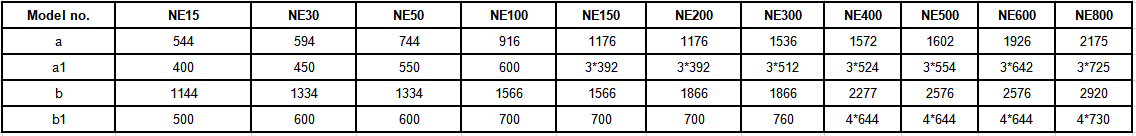

Technical Parameter and Specifications

Our engineering team can walk you through the design process and help you choose the suitable bucket elevator that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms