Tubular Screw Conveyor

Tubular Screw Conveyor

Tubular Screw Conveyor

Tubular screw conveyor, commonly known as auger, is a widely used conveying equipment in minerals, feed, grain and oil, construction industry. From the perspective of the displacement direction of conveyed materials, the screw conveyor is divided into two types: horizontal tubular screw conveyor and vertical tubular screw conveyor, mainly used for horizontal conveying and vertical lifting of various powdery, granular and small bulk materials.

Applications

The tubular screw conveyor is the main unit of mechanized transportation in various industrial and agricultural departments, which can reduce labor intensity and improve work efficiency in transportation work, and has a wide range of applications. It is suitable for various industries, such as building materials, chemical industry, electric power, metallurgy, coal, grain and other industries, and is suitable for horizontal or inclined conveying powdery, granular and small block materials, such as coal, ash, slag, cement, grain, etc., and the material temperature is less than 200 °C. It is not suitable for conveying viscous materials and those are easy to deteriorate and agglomerate.

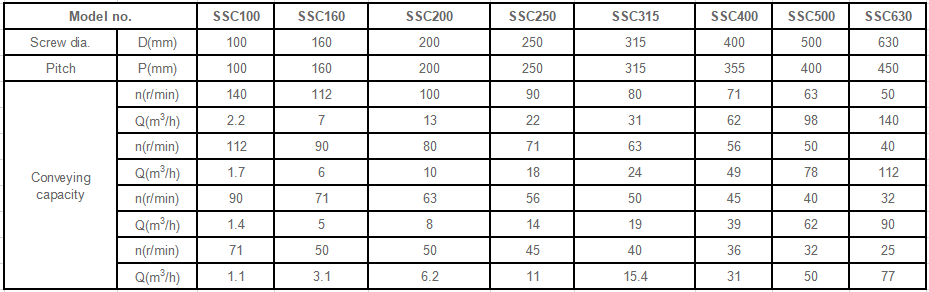

Shafted Screw Conveyor Parameter and Specifications

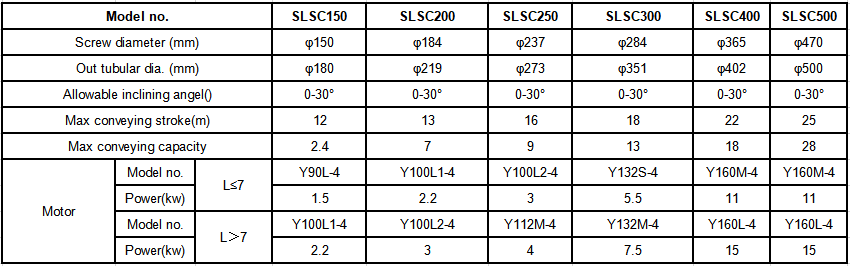

Shaftless Screw Conveyor Parameter and Specifications

Working Principle

The working principle of the screw conveyor is that the rotating spiral blades will move the material and carry out screw transportation, and the material and the screw conveyor blades will rotate and advance together by relying on the weight of the material itself and the friction resistance of the screw conveyor casing to the material(When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow). The rotating shaft of the screw conveyor is welded with spiral blades, and the surface type of the blade has solid surface type, belt surface type, blade surface type and other types according to the different conveyed materials. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction, and if the fuselage is long, the middle hanging bearing should be added.

Features and Functions

1. Structure: Consists of a helical screw blade (the "flight") that rotates within a tube or trough. The screw can be continuous or broken into segments.

2. Material Movement: As the screw rotates, it pushes the material along the conveyor's length. This movement can be horizontal, inclined, or even vertical.

Advantages

● Efficient and effective for moving bulk materials.

● Can handle a wide range of materials, including wet, dry, sticky, or abrasive.

● Customizable in length, diameter, and design to fit specific needs.

● Can be enclosed to prevent contamination or dust.

Types

Horizontal Screw Conveyors: Ideal for transporting materials over short distances.

Inclined Screw Conveyors: Used when materials need to be elevated.

Vertical Screw Conveyors: For lifting materials to higher levels.

Flexible Screw Conveyors: Can bend and twist to navigate around obstacles.

Applications

Agriculture: Transporting grains, feed, and other agricultural products.

Food Processing: Handling ingredients like flour, sugar, and other bulk foods.

Mining and Minerals: Moving heavy materials like ore, coal, and other mined products.

Manufacturing: Transporting raw materials or waste products within a production process.

Operation and Maintenance

Speed: Controlled by varying the screw's rotation speed.

Wear and Tear: Components like the screw and trough can wear out over time, especially with abrasive materials, requiring regular maintenance and occasional replacement.

Blockages: Regular inspections are necessary to prevent and address any potential blockages in the conveyor.

Our engineering team can walk you through the design process and help you choose the suitable screw conveyor that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms