TD Hopper Type of Bucket Elevator

TD Hopper Type of Bucket Elevator

Overview

A bucket elevator is a type of mechanical conveying system used to vertically transport bulk materials. The TD hopper type of bucket elevator adopts rubber belt as traction component. It has the advantages of rich specifications, large conveying capacity, high lifting height, stable operation and long service life. The casing is folded and welded with good rigidity and beautiful appearance. If the heat-resistant belt is used, the temperature of the conveyed material can reach 150 °C, which is suitable for conveying non-(or low) abrasive bulk materials. It is not suitable for conveying large, highly rigid and difficult digging materials.

Features and Applications

The hopper of this bucket elevator is arranged intermittently, and loading by "digging method" and unloaded by "centrifugal feeding method". The traction mechanism of this bucket elevator is two ring chains, which are transmitted by friction between the chains and the upper sprocket, so it runs smoothly and is a lighter fast elevator. This bucket elevator is suitable for conveying powdery, granular and small pieces of non-abrasive materials, such as coal, cement, stones, sand, clay, ore, grains, minerals, etc. Since the traction mechanism of the bucket elevator is a ring chain, it allows the conveyed materials with higher temperatures. In order to adapt to the different extraction and throwing characteristics of the conveyed materials, this bucket elevator is equipped with two kinds of hoppers: deep round bottom shape and shallow round bottom shape. The deep round bottom shaped hopper is suitable for conveying dry, loose and easy-to-throw materials, such as cement, coal lumps, dry sand and crushed stone. The shallow round bottom hopper is suitable for conveying wet, easy to agglomerate and difficult to throw materials, such as wet sand, molding sand, etc. There are two models of HL type bucket elevator: HL-300 and HL-400. The conveying capacity of the bucket elevator is 16~47.2 cubic meters per hour, and the height of the elevator is 4.5~30 meters.

Key Components

1. Buckets: These are containers attached to a belt or chain and are used to scoop up and lift the material.

2. Belt or Chain: The buckets are attached to this, and it moves in a continuous loop to transport materials.

3. Drive Mechanism: This includes motors and gearboxes that power the belt or chain.

4. Top and Bottom Pulleys: Also known as sprockets when a chain is used, these are used to guide and drive the belt or chain.

5. Casing: Encloses the system to protect the materials and the machinery from external elements.

6. Inlet and Outlet Sections: Where the material is loaded into the buckets and where it is discharged.

Types of Bucket Elevators

1.Centrifugal Discharge Elevators: Suitable for handling dry, free-flowing materials. The buckets are spaced apart, and the material is thrown out by centrifugal force as the buckets pass over the head pulley.

2.Continuous Discharge Elevators: Used for handling sluggish or fragile materials. The buckets are closely spaced, and the material flows out by gravity as the buckets move past the head pulley.

3.Positive Discharge Elevators: Combines features of both centrifugal and continuous discharge elevators. Suitable for handling larger, heavier, or abrasive materials.

Advantages

● Efficiency: Capable of transporting large volumes of materials vertically.

● Space-Saving: Vertical transport uses less horizontal space compared to other conveying systems.

● Versatility: Can handle a wide range of materials, from fine powders to large, abrasive products.

● Durability: Designed to withstand harsh industrial environments and continuous operation.

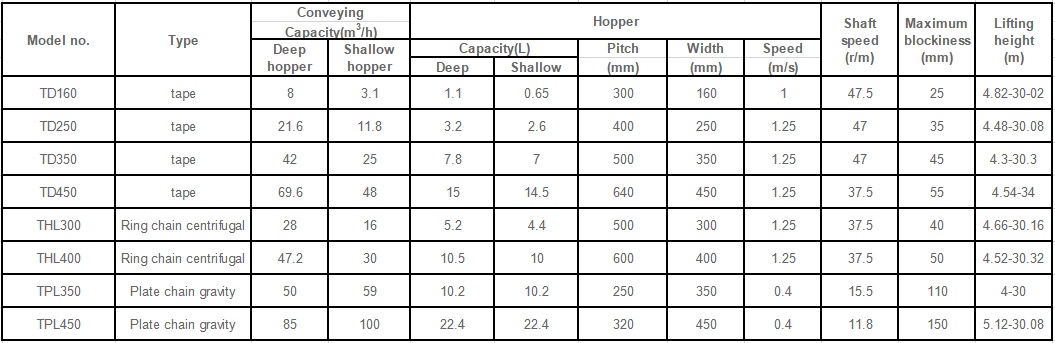

Specifications

Note:

The volume of the hopper in the table is the volume of the hopper when it is filled with water, which is similar to the actual filling amount, so the filling coefficient is not considered in the calculation formula of the conveying volume, and the filling coefficient should be determined according to the particle size of the material during the specific selection, so as to correct the conveying volume given in this table.

This parameter table is for reference only and is subject to change according to the customer's geographical environment conditions and requirements.

Our engineering team can walk you through the design process and help you choose the suitable bucket elevator that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms