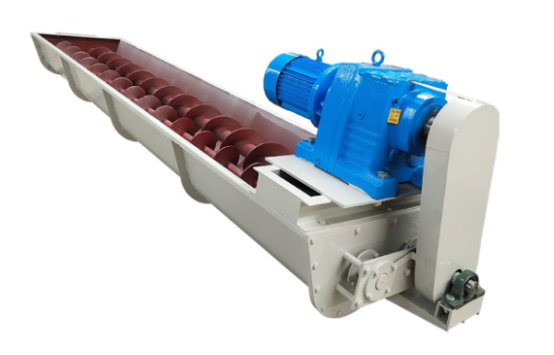

U-shaped Screw Conveyor

U-shaped Screw Conveyor

Performance and Characteristic of the U-shaped Screw Conveyor

The U-shaped screw conveyor has good structural sealing performance, and can be used for intermediate loading and multi-point loading of materials in several positions, which is safe, convenient and reliable in operation. The bearings at the frond and rear ends of the screw conveyor are placed outside the shell, which reduces the intrusion of dust into the bearing chamber and improves the service life of the key parts of the screw conveyor. The hanging bearing adopts sliding bearing, equipped with dust-proof sealing device. The hanging shaft and the screw shaft are connected by slider. When disassembling the screw shaft, the driving device does not need to be removed; when disassembling the lifting bearing, the screw shaft does not need to be removed, and the lifting bearing can be lubricated without removing the cover plate. Therefore, the whole set of screw conveyor is of high reliability, long service life and strong adaptability.

Scope of Application of the U-shaped Screw Conveyor

The U-shaped screw conveyor has been widely used in building materials, metallurgy, chemical industry, machinery, light industry, grain and food industries. The U-shaped screw conveyor is suitable for conveying powdery, granular, and small block materials, such as cement, fly ash, grain, fertilizer, mineral powder, sand, soda ash, etc. It is not suitable for conveying viscous materials and those are easy to deteriorate and agglomerate.

Selection Reference for the U-shaped Screw Conveyor

The environment working temperature of the U-shaped screw conveyor is usually -20~40 °C, and the temperature of the conveyed materials is generally -20~80 °C. seven screw diameters: 150, 200, 250, 300, 400, 500, 600;

nine standard revolutions (revolutions per min): 20, 30, 35, 45, 60, 75, 90, 120, 150;

screw length: from 3 meters to 30 meters, which can be flexibly selected according to the actually needed conveyor length.

Working Principle

The working principle of the screw conveyor is that the rotating spiral blades will move the material and carry out screw transportation, and the material and the screw conveyor blades will rotate and advance together by relying on the weight of the material itself and the friction resistance of the screw conveyor casing to the material(When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow). The rotating shaft of the screw conveyor is welded with spiral blades, and the surface type of the blade has solid surface type, belt surface type, blade surface type and other types according to the different conveyed materials. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction, and if the fuselage is long, the middle hanging bearing should be added.

Features and Functions

1. Structure: Consists of a helical screw blade (the "flight") that rotates within a tube or trough. The screw can be continuous or broken into segments.

2. Material Movement: As the screw rotates, it pushes the material along the conveyor's length. This movement can be horizontal, inclined, or even vertical.

Advantages

● Efficient and effective for moving bulk materials.

● Can handle a wide range of materials, including wet, dry, sticky, or abrasive.

● Customizable in length, diameter, and design to fit specific needs.

● Can be enclosed to prevent contamination or dust.

Types

Horizontal Screw Conveyors: Ideal for transporting materials over short distances.

Inclined Screw Conveyors: Used when materials need to be elevated.

Vertical Screw Conveyors: For lifting materials to higher levels.

Flexible Screw Conveyors: Can bend and twist to navigate around obstacles.

Applications

Agriculture: Transporting grains, feed, and other agricultural products.

Food Processing: Handling ingredients like flour, sugar, and other bulk foods.

Mining and Minerals: Moving heavy materials like ore, coal, and other mined products.

Manufacturing: Transporting raw materials or waste products within a production process.

Operation and Maintenance

Speed: Controlled by varying the screw's rotation speed.

Wear and Tear: Components like the screw and trough can wear out over time, especially with abrasive materials, requiring regular maintenance and occasional replacement.

Blockages: Regular inspections are necessary to prevent and address any potential blockages in the conveyor.

Our engineering team can walk you through the design process and help you choose the suitable screw conveyor that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms