Air Conveying Chutes(ACC)

Air Conveying Chutes(ACC)

Overview

The air conveying chute(ACC) is a device that uses air flow to transport cement and other easily fluidized powder or granular materials in bulk along the pipeline, and it is not suitable for materials with large particle size, plenty of moisture and poor fluidization performance. This chute uses a high-pressure centrifugal fan as the power source, so that the materials in the sealed conveying chute keep the fluidized state and flow slowly to the downward end. There are no transmission parts needed in the device, the sealing operation and management are convenient, easy to start and stop, the working noise is small, no lubrication is required, almost no maintenance is required, it is light in weight, less in power consumption, strong in conveying capacity, and easy to change the conveying direction.

The chute is composed of two slots, the upper and lower slots, and in the middle it is separated by a special wear-resistant chemical fiber as a permeable layer, which doubles the life of the chutes with a permeable cloth. The high-pressure air enters from the lower slot and passes through the permeable layer into the upper slot, so that the materials in the upper slot come into a fluid state and flow under the action of gravity to achieve the purpose of transportation. According to the different inhalation methods, the ACC device can be divided into three types, the suction type, the blow-in type and their combined type.

Working Principle

The working principle of the air conveying chute is to use the kinetic energy of the air flow to make the powder or granular materials in a suspended state and transport along the pipeline to the target position with the air flow.

(1) The suction type. After the exhaust fan is started, the whole system becomes a certain vacuum state. The materials enter the suction nozzle under the action of pressure difference, and are sent to the separator at the discharge place along the conveying pipe, then, the material is separated from the air flow and discharged from the bottom of the separator, and the air flow is purified by the dust collector and then discharged into the atmosphere through the muffler. The advantage is that it is easy to feed materials and can draw materials from several places at the same time. However, the conveying distance is short and the productivity is low, as well as high requirements of tightness.

(2) The blow-in type. The blower presses the air into the conveying pipe. The material is supplied from the feeder. The mixture of air and material is blew in along the conveying pipe to the discharge. The material is discharged after the separator, and the air is purified by the dust collector and discharged into the atmosphere. The characteristics of the blow-in type are contrary to that of the suction type. It can convey the material to several places at the same time, with longer conveying distance, higher productivity, but complex structure.

(3) The combined type of suction and blow-in. It is a combination of the above two forms.

Remind: this device is not suitable for materials with large particle size, plenty of moisture and poor fluidization.

Applications

The ACC equipment is for conveying powdery or granular materials in bulk that are easy to fluidize. The conveying object is powder, granular and powder-mixed dry materials with water content of ≤1% and temperature of ≤150°C. The air conveying chute can be used for cement, fly ash and other powdery materials that are easy to fluidize. The chute uses a high-pressure centrifugal fan (9-19:9-26 type) as the power source, so that the material in the closed conveying chute keeps fluidized and slowly flows to the inclined end. The ACC equipment has no transmission part, and adopts a new type of polyester permeable layer. It’s easy to seal and manage, light in weight, low in power consumption, strong in conveying force, and easy to change the conveying direction.

Influencing Factors

1. Air permeability of the sporous plate. There are many materials for porous plates, such as porous ceramic plates, composite materials, etc., which are selected according to the specific situation.

2. Install the inclination angle. The optimal inclination angle of air conveying chute is 5°-6°.

3. The width of the air conveying chute. The conveying volume and the width of the chute can be expressed in formula as follows:

M=K*p*B2;

M=conveying capacity of air conveying chute , unit: kg/s;

K = constant;

p = bulk density of fly ash in the chute when it is completely fluidized, unit: kg/m3;

B = width of chute groove , unit: m;

4. Air consumption. The working pressure of fluidized air in the air conveying chute is generally 3.5-5Kpa, and the optimal air consumption is 2-3m3/min, that is, the air consumption per minute of the effective ventilation area of the pore-shaped plate is 2-3m3.

5. The moisture content of fly ash. Under normal circumstances, the moisture content of fly ash is less than 1%, if the moisture content is high, it will affect the conveying efficiency and even cause blockage.

6. Initial velocity of fly ash. A certain initial speed is conducive to chute conveying, especially for short chutes.

7. Conveying distance. For long-distance pneumatic transportation, the corresponding air inlet must be added in the length of the chute to ensure that the air enters the chute evenly and maintains the optimal fluidization of fly ash.

8. Control of fly ash feed amount. The air conveying chute must be fed evenly to avoid the blockage of the chute caused by instantaneous overfeeding.

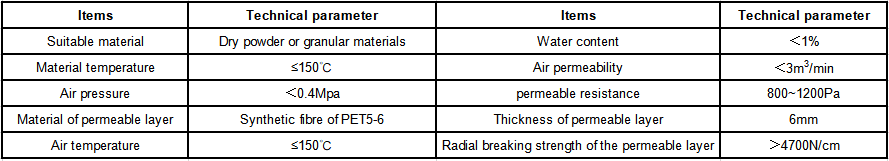

Basic Information

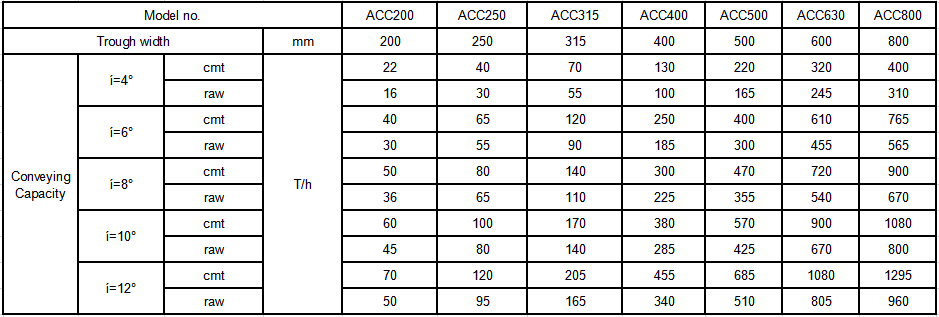

Conveying Capacity of ACC Air Conveying Chute

Note:

1. “cmt” in this table means cement; “raw” refers to the raw material.

2. The conveying distance of the air conveying groove is generally within 30m;

3. Non-standard length is generally selected by multiples of 250mm;

4. 90°bending groove is divided into left and right directions;

5. The tee groove is divided into two directions: left and right;

6. The four-way groove is divided into two forms: one in and three out, and three in and one out.

Our engineering team can walk you through the design process and help you choose the suitable air conveying shute that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms