High-speed Disperser

High-speed Disperser

Overview

The high-speed disperser has a variety of functions, such as hydraulic lifting, 360-degree rotation, and stepless speed regulation. It can be configured with 2-4 containers at the same time, and the capacity of each container is 1000-2000L, which can be customized. The lifting system of the double-shaft high-speed disperser is configured separately from the main body, which makes the operation more flexible and convenient. The hydraulic cylinder of the lifting system is professionally designed, safe and reliable, and the hydraulic lifting stroke is 900-2100mm, etc. The 360-degree rotation function can better realize the multi-purpose of one machine, and can be transferred from one container to another in a very short time, which greatly improves the work efficiency and reduces the labor intensity. The speed regulation mode can be in various forms, such as stepless speed regulation, electromagnetic speed regulation, frequency conversion speed regulation (for water-based coatings) and explosion-proof frequency conversion speed regulation (for oil-based coatings). The stepless speed regulation function can fully meet the different process requirements in various processes, and different speeds can be selected according to different process stages, and the speed regulation range is 0-1450 r/min. The dispersion shaft and dispersion disc of the double-shaft high-speed disperser are made of high-quality stainless steel, which has the advantages of wear resistance and corrosion resistance. The high-speed disperser is equipped with a user-friendly electronic control panel, which enables users to master the correct use of the high-speed disperser in a relatively short time. Stirring and dispersing at medium or high speed can quickly dissolve the material and make the particles finer; When stirring and dispersing, the air is very little absorbed, and the mixing and shearing effect is good.

Working Principle

In order to complete the processes of dispersion, wetting, depolymerization and stabilization of solid&liquid materials, the dispersion disc of the disperser rotates at high speed in the container, so that the slurry rolls at high speed to form a circular flow, resulting in a strong vortex. The slurry descends to the bottom of the container in a spiral rotation, and a turbulent flow is formed at the edge of the dispersion disc, and the slurry and particles are strongly impacted and sheared by the dispersion disc, forming two beams up and down, so that the slurry can be fully turned and circulated. The slurry becomes a laminar flow state below the dispersion plate, and the slurry layers with different flow rates diffuse each other to play a dispersing role.

Scope of Application

High-speed dispersers are widely used in coatings, dyes, paints, inks, food, cosmetics, medicine, pesticides, glues, papermaking and other industries. Among them, the explosion-proof disperser is mainly used for the production of solvent-based flammable and explosive chemical products, such as coatings, paints, inks, color pastes, floor paints, road marking paints, polyurethane paints, alkyd enamels, blending paints, etc.

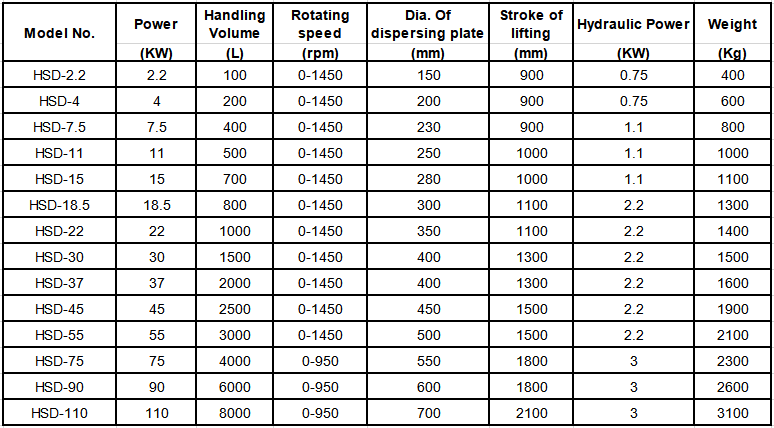

Specifications Selection Sheet

Note:

*The processing capacity in the table is the data measured when "water" is used as the medium, and the selection should be calculated according to the viscosity of the product, solid-liquid ratio and other parameters.

*If there are high temperature, high pressure, flammable, explosive, corrosive and other working conditions, detailed data must be provided for additional selection and customization.

*The data and pictures in this table are subject to change without prior notice, and the correct parameters are subject to the actual product provided.

*This table does not include all products, please contact our sales engineer for more information.

Our engineering team can walk you through the design process and help you choose the suitable high-speed disperser that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms