Real Stone Paint Mixer

Real Stone Paint Mixer

Introduction of Real Stone Paint

A real stone paint is a very thick architectural paint. It is formulated with a synthetic resin emulsion, different grades of colored sand grains and various additives. Its production process is different from that of general architectural coatings. In addition, since there is no need for high-speed mixing or crushing, what is mainly needed is to conduct the mixing processes, it is necessary to use an appropriate mixer to mix the thick slurry instead of ordinary paint manufacturing equipment. For example, high-viscosity paints such as real stone paint, texture paint, colorful paint, colorful water-in-water paint, imitation stone paint, stone paint, etc. All these only need to be stirred at low speed and evenly mixed with a real stone paint mixer.

Introduction of Real Stone Paint Mixer

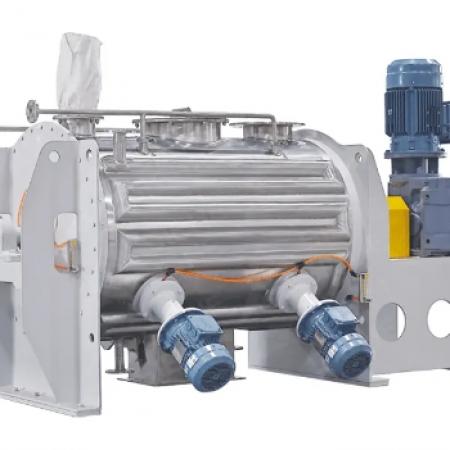

The real stone paint mixer can integrate the function of wall scraping and mixing. It can make the material roll three-dimensionally during operation, so that the material can be mixed quickly and evenly, and effectively, eliminating dead corners and wall hanging. Feed control, discharge control, stirring control, and other manual and automatic controls can be performed during the mixing process. The real stone paint mixer is mainly composed of a mixing system and an electric control system. The mixing system consists of a mixing drum, mixing blades and a driving device, while the electronic control system involves the starting, stopping and speed adjustment of the mixer. This type of mixer usually uses a rotating or reciprocating method to mix the material well in the barrel. In practice, employees need to put binders, pigments, fillers and other raw materials into the mixing tank according to the requirements of the real stone paint formula, and mix them evenly through the work of the mixer to get the ideal real stone paint products. Weighing and metering devices, liquid level measuring devices, temperature control devices, etc. can be selected and configured according to process requirements. The inner wall of the stirring tank is polished and equipped with a wall scraper to ensure that the materials are stirred evenly and discharged cleanly; The stirring and transmission movement is stable and the noise is low to ensure the smooth progress of production; The structural design is user-friendly and easy to operate.

Working Principle of Real Stone Paint Mixer

The horizontal real stone paint mixer adopts multi-spiral belt mixing, which can mix materials evenly and quickly. The equipment adopts the method of directional spinning and unwinding, which greatly reduces the waste. Small occupying area, simple operation, convenient maintenance, high mixing uniformity, less waste, good sealing, no vibration, fast rotation speed, fast discharging, all the above advantages greatly improve the work efficiency and reduce the work intensity. Also, with advantages of energy saving, environmental protection, labor and time saving.

Body Structure of Real Stone Paint Mixer

The device has a horizontal U-shaped structure. The tanks are made of carbon steel and stainless steel (201/301), and the inner and outer spiral bands are staggered. The mixing speed is high and the uniformity is very good. The bearings and stirring blades are made of carbon steel/manganese stainless steel. Cast steel, polished blade, durable and easy to use; The equipment has a 90-degree rotation structure, which can discharge residues during operation, which is more convenient to clean, reducing labor intensity, and improving production efficiency; All parts have good sealing technology, and the material discharge port is sealed with a waterproof butterfly valve, which reduces the problem of material leakage and dripping during the production process. The whole production line is composed of real stone paint mixer, control cabinet and screw elevator (bucket elevator is recommended for equipment output over 20 tons). It can be equipped with a reasonable model according to customer needs. The maximum output can reach 40T.

The mixing tank body, mixing tank cover, agitator, shaft seal, etc. can be made of carbon steel or stainless steel according to different process requirements; The mixing tank body and the mixing tank lid can be connected by flange sealing or welding. The main body and lid of the mixing tank can be opened according to the process requirements of the pipe hole engineering processes, such as feeding, discharging, observation, temperature measurement, pressure measurement, steam distillation, and safety ventilation; The upper part of the mixing tank cover is equipped with a transmission device (motor or reducer), and the agitator in the mixing box is driven by a transmission shaft. Shaft sealing devices can take various forms, such as mechanical seals, packing, labyrinth seals, etc. (as determined by the user's needs); Due to the different requirements of users for the production process, the agitator can be configured in various shapes, such as the paddle type , the anchor type, the frame type and the spiral type.

Features of Real Stone Paint Mixer

1. The equipment adopts horizontal installation, which occupies a small area, has less investment, convenient feeding, first-class mixing effect and higher efficiency.

2. The structure of this equipment is reasonable, there is worm mixing in the barrel, and the peripheral spiral rotation is large, so that the material can be mixed and stirred evenly. It is suitable for the mixing of high-viscosity materials or powdery materials.

3. There is a scraper on the tank wall, which will rotate in time to clean the contaminants, so that there is no sticky material on the tank wall, which is more corrosion-resistant and economical.

4. Stable operation, low noise. The stainless steel materials used in the horizontal real stone paint mixing tank are wear-resistant and easy to clean. The blades are mirror-polished, easy to clean, simple to operate, low maintenance rate and high performance.

5. The mechanical seal and the internal floating ring can achieve the effect of dripping, and the ordinary carbon steel and glass fiber reinforced plastic and stainless steel completely solve the oxidation problem of the inner tank.

6. Equipped with electromagnetic speed regulating motor, cycloidal pin wheel reducer, exquisite material selection, reasonable design, U-shaped top open type, easy to clean.

The Importance of Choosing A High-efficiency Real Stone Paint Mixer

Choosing an efficient stone paint mixer is related to product quality and production efficiency. A high-performance mixer should have the ability to shorten mixing time, improve production efficiency, save energy consumption, and ensure the uniformity and stability of the real stone paint mixture. Therefore, when choosing a mixer, enterprises should not only consider the basic performance of the mixer, but also consider its ease of operation, maintenance cost, durability and production effect.

The Choice of Real Stone Paint Mixer Model and Configuration

Different models of real stone paint mixers meet the needs of different scale production. The small mixer meets the need of small batch production, while the large fully automatic mixing equipment meets the needs of large-scale industrial production. When choosing the model of the mixer, enterprises need to consider their own production capacity, capital budget and the actual situation of the production site. In terms of configuration, modern real stone paint mixers usually have functions such as automatic feeding, timing mixing, and automatic discharging, which can greatly improve the work efficiency and reduce labor costs.

How to Care For and Maintain A Real Stone Paint Mixer

In order to ensure the normal operation of the real stone paint mixer and prolong its service life, regular care and maintenance are essential. Daily maintenance includes cleaning the mixing tank, checking the wear of the mixing blades, lubricating the transmission parts, etc. Proper maintenance of the equipment not only reduces the failure rate, but also ensures the mixing effect and avoids the increase in product rejection rate due to uneven mixing. Therefore, the operator should operate and maintain the mixer in strict accordance with the instruction manual to ensure the stable and reliable operation of the equipment.

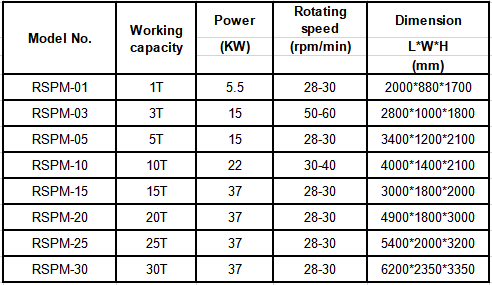

Technical Data and Specifications

Our engineering team can walk you through the design process and help you choose the suitable real stone paint mixer that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms