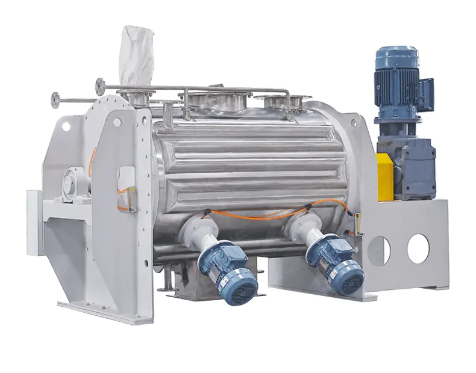

Plough Shear Mixer

Plough Shear Mixer

Overview

The plough shear mixer, also known as the coulter mixer, is composed of a circular tank, a transmission mechanism, a plough shear, a plow blade, a flying knife, a drive controlling device. When the equipment is running, the spindle drives the coulter to rotate in circles along the inner tank wall at an appropriate speed, while the flying knife is directly driven by the motor and rotates at high speed. Due to the rotation and reversal of the coulter, the material is constantly turned and rolled in the tank, realizing the accelerated movement and repeated interspersing in the three-dimensional space, and at the same time, when the material flows through the high-speed rotating flying knife, it is sheared at high speed, forming a violent impact, shearing and diffusion effect. Therefore, the movement trajectory of the powder and granules in the mixing equipment is criss-crossed, hitting each other, generating a strong vortex, which quickly and evenly mixed the materials in a very short time. In recent years, with the continuous improvement of technology and environmental protection awareness in the mixing industrial, people has paid more attention to the safety, stability, efficiency and environmental protection characteristics of powder mixing equipment when conducting the design and innovation jobs. In terms of material, the plough shear mixer can choose from carbon steel, stainless steel, high alloy and other steels to match the properties of the materials, such as particle size, corrosion and chemical reactions, etc. Combined with relevant industry standards and customer feedback, with continuous innovation, Zhongcheng Lijing has obtained a significant recognition of the plough shear mixer in building materials, chemical industry, metallurgy and other industries.

Performance Characteristics

1. It is suitable for mixing materials of powdery, granular, fibrous and agglomerate;

2. It is suitable for the mixing and granulation operations for powder and liquid;

3. It integrates stirring, crushing, dispersing, humidification and dust filtration;

4. The mixing speed and time is adjustable, which can produce high-quality mixture

5. It can be mixed, heated, cooled, dried and chemically reacted;

6. Aggregate particle size: 0-4.75mm; Volume range of 0.5-6 m3.

Plough Shear Mixer Structure

(1) There are two kinds of tanks: round and U-shaped. The mechanical strength of the round tank is higher; the U-shaped structure is more reasonable, and it is more convenient to manufacture and use.

(2) Coulter: the coulter is the key part of this mixing equipment. The two sides of the coulter are made flat or curved, and the bottom is made into arcs or serrations. The coulter is mounted on the spindle and can be adjusted radially to ensure the proper clearance between the bottom of the coulter and the tank wall. The coulter should be made of harder material to avoid wear and tear.

(3) Flying knives: there are two types of flying knives, one is multi-blade and the other is petal-shaped.

(4) Discharge valve: the discharge valve is installed in the middle of the bottom of the horizontal tank, and the plug valve is generally used, in order to reduce the amount of discharge residue, a large opening valve is also commonly used, and there must be no dead ends area of the valve plate.

Advantages and Precautions of Plough Shear Mixer

1. Advantages

(1) The mixing effect of the plough shear mixer is good, and it can reach more than 99.9% of the mixing uniformity.

(2) The mixing speed is fast and the efficiency is high, which is more suitable for processing large quantities of materials.

(3) It is suitable for materials that are easy to aggregate, easy to agglomerate and easy to bond, and it can avoid the material accumulation and sticking to the wall.

2. Precautions

(1) The material in the plough shear mixer should not exceed half level of the container.

(2) For vulnerable materials, a low-speed plough shear mixer should be considered.

(3) The plough shear mixer should be cleaned frequently to avoid rust and cross-contamination.

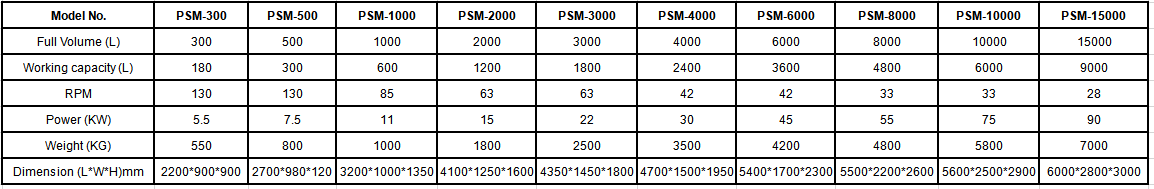

Technical Data and Specification

Note:

*The data and pictures in this table are subject to change without prior notice, and the correct parameters are subject to the actually provided product.

*This table does not include all the sizes of the mixer, please contact our sales engineer for more information.

Our engineering team can walk you through the design process and help you choose the suitable plough shear mixer that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms