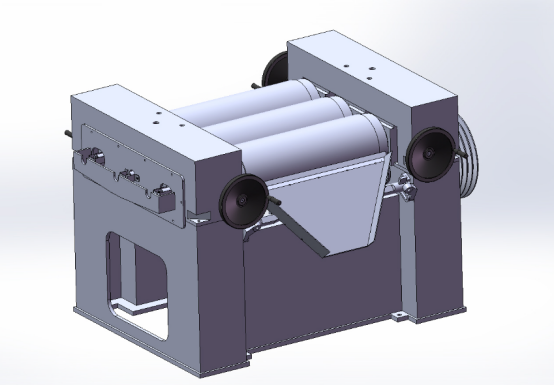

Three-roll Grinder

Three-roll Grinder

Basic Introduction

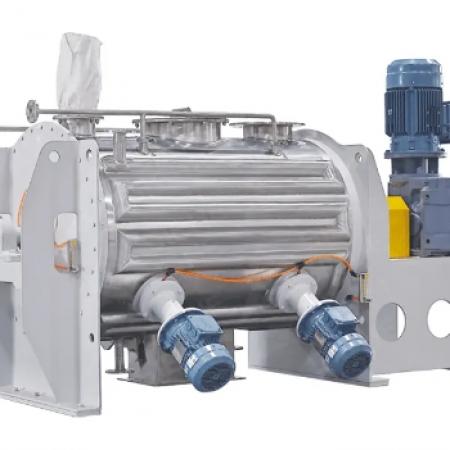

The working principle of the three-roller mill is to achieve the grinding effect by squeezing and rubbing the surfaces of three horizontally positioned rollers with different running speeds . The three-roller mill is the most effective grinding and dispersing equipment for high-viscosity materials, mainly used for the grinding of paints, inks, pigments, plastics, soaps, cosmetics, ceramics, rubber and other liquid slurries and paste-like materials, especially suitable for grinding products with high dispersion viscosity but fine particle size requirements and materials that are difficult to circulate and grind or are not resistant to circulation by the sand mill.

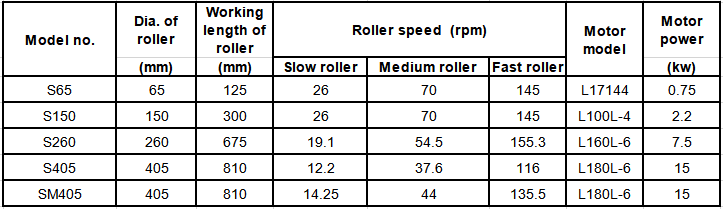

Product Parameters

1. The roller of the hydraulic three-roller grinding machine is made of cold hard alloy cast iron by centrifugal casting, with a surface hardness of more than HRC70°, which is a high-strength and wear-resistant grinding machine part. The roller has strong toughness, therefore, the properties of the roller will not be affected due to external pressure and temperature.

2. The outer circle of the roller is ground with high precision, precisely and delicately, which can make the grinding fineness of the material reach less than 5μm, and produce uniform and delicate high-quality products.

3. The transmission system of the hydraulic three-roller grinder adopts multi-row chain for soft start, which has high transmission efficiency, stable operation and no noise.

4. Adjust the flat hand-wheel screw to change the gaps between the rollers, and then, the required particle size of the grinding material can be obtained, which is simple and accurate, and easy to operate.

5. The hydraulic three-roller grinder is equipped with a cooling device, which can dissipate the heat generated by the roller when it is working to ensure continuous work; It is suitable for many varieties and is easy to change colors.

Working Principle

Working principle of three-roller grinder is as follow: three-roller grinder achieves grinding effect by pressing the surface of three horizontal rollers against each other and rubbing at different speeds.

Specifications

Our engineering team can walk you through the design process and help you choose the suitable three-roll grinder that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms