High-efficient Washing Tower (HWT)

High-efficient Washing Tower (HWT)

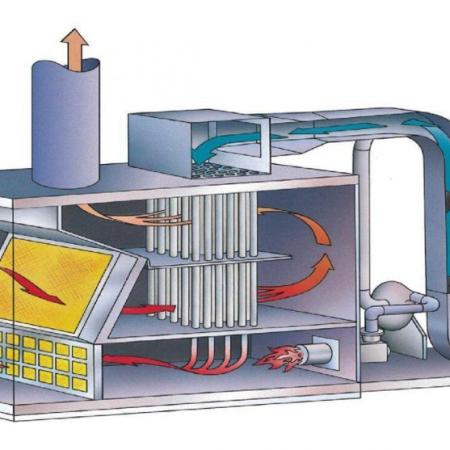

Working Principle of HWT

The washing tower is also called the spray tower. The main operation mode of the washing tower is that the exhaust gas is introduced into the purification tower by the air duct and passes through the packing layer, the exhaust gas and the absorption liquid are fully in contact and take absorption and neutralization reaction, as a result, the acid mist, organic waste gas and VOCs are purified, and then dehydrated and defogged by the defogging plates and discharged into the atmosphere by the fan. The absorbent liquid is pressurized by a pump at the bottom of the tower and sprayed down at the top of the tower, and then returned to the bottom of the tower for recycling. The purified exhaust gas meets the emission requirements of local emission standards and is lower than the national emission standards.

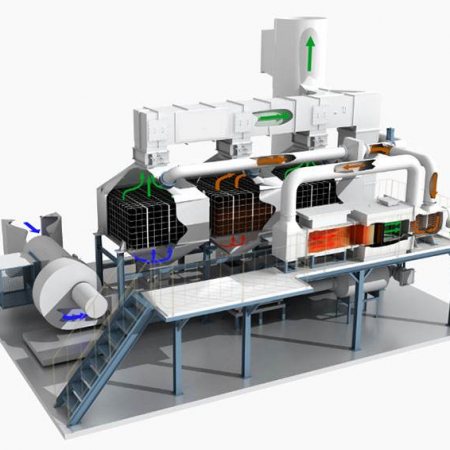

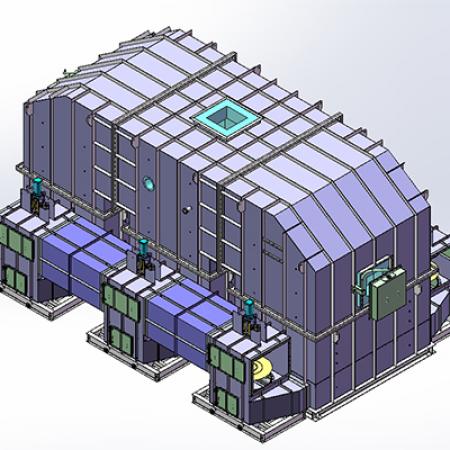

Structural Composition

The structural composition of the washing tower is diverse, and it can be divided into single tower and double tower according to the project application site, as well as vertical washing tower and horizontal washing tower. It is segmented connected by flanges. Specifically, it is composed of a liquid storage tank, a tower body, an air inlet section, a spray layer, a packing layer, a swirl defogging layer, an air outlet cone cap, and an observation window.

The material of the washing tower body is commonly used in carbon steel, stainless steel, PP, FRP or FRP and other materials. PP and FRP are often used in chemical absorption towers, which have the characteristics of acid resistance, alkali resistance and corrosion resistance, and stainless steel materials can be used for high-temperature exhaust gas. The filler can be Pall ring, Lassi ring, etc., and the filler materials can be PP, plastic, ceramic, 304 stainless steel and other materials. The mist eliminator includes swirl plate mist eliminator, or wire mesh mist eliminator, etc.

Scope of Application

washing towers are widely used in food, chemical, plastic, electronics, automotive spraying and coating, mold, wood, metallurgy, machinery, petroleum, power plants, solar energy, alloy grinding and other industries.

1) Treatment of harmful gases such as H2S, SOx, NOx, HCI, NH3, Cl2, H2SO4, VOCs and other gases such as dust, VOCs, inorganic acid and alkaline exhaust gases, organic exhaust gases, etc.;

2) Deodorization devices for garbage transfer sites, physical treatment, garbage incineration, and sewage treatment sites;

3) Process exhaust treatment in the semiconductor optoelectronics industry;

4) Waste gas treatment of seepage water storage tank in landfill;

5) Treatment of exhaust gas emitted from incinerators and industrial furnaces.

Technical Parameters and Specification Selection Sheet

Model No. | Handling gas volume(Nm3/h) | Concentration of exhaust gas (mg/m3) | Types of exhaust gas | Thickness of filter material (mm) | Layers of filter material | Dimension | ||

Tower dia.(mm) | Height (mm) | Inlet and outlet port (mm) | ||||||

HWT-3 | 3000 | ≦400mg/m3 | Acid mist (H2S04), hydrogen chloride(HCl)and hydrogen fluoride(HF), chromic acid mist(CrO3),hydrogen cyanide acid(HCN), hydrogen sulfide(H2S), ammonia(NH3),alkaline steam | 600 | 2 | Φ800 | 3900 | Φ300 |

HWT-5 | 5000 | 600 | 2 | Φ900 | 4110 | Φ400 | ||

HWT-6 | 6000 | 600 | 3 | Φ1000 | 4110 | Φ450 | ||

HWT-7 | 7000 | 600 | 3 | Φ1100 | 4110 | Φ500 | ||

HWT-9 | 9000 | 600 | 3 | Φ1200 | 4000 | Φ550 | ||

HWT-10 | 10000 | 600 | 3 | Φ1200 | 4380 | Φ600 | ||

HWT-13 | 13000 | 600 | 3 | Φ1400 | 4680 | Φ650 | ||

HWT-15 | 15000 | 600 | 3 | Φ1500 | 4530 | Φ700 | ||

HWT-18 | 18000 | 600 | 3 | Φ1700 | 4680 | Φ750 | ||

HWT-20 | 20000 | 600 | 3 | Φ1800 | 4840 | Φ800 | ||

HWT-22 | 22000 | 600 | 3 | Φ2000 | 4640 | Φ850 | ||

HWT-25 | 25000 | 600 | 3 | Φ2100 | 4650 | Φ850 | ||

HWT-27 | 25000 | 600 | 3 | Φ2200 | 4950 | Φ900 | ||

HWT-30 | 30000 | 600 | 3 | Φ2450 | 4850 | Φ950 | ||

HWT-35 | 35000 | 600 | 4 | Φ2600 | 5150 | Φ1000 | ||

HWT-40 | 40000 | 600 | 4 | Φ2800 | 5250 | Φ1100 | ||

Remarks: according to customer needs, it is equipped with sprinkler pipe, ball valve, flow meter, differential pressure meter, integrated grid, mist eliminator, water tank cover plate, new water replenishment/drainage set, large flow water pump, etc. | ||||||||

Our engineering team can walk you through the design process and help you choose the suitable high-efficient washing tower (HWT) that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms