Regenerative Catalytic Oxidizer (RCO)

Regenerative Catalytic Oxidizer (RCO)

Overview

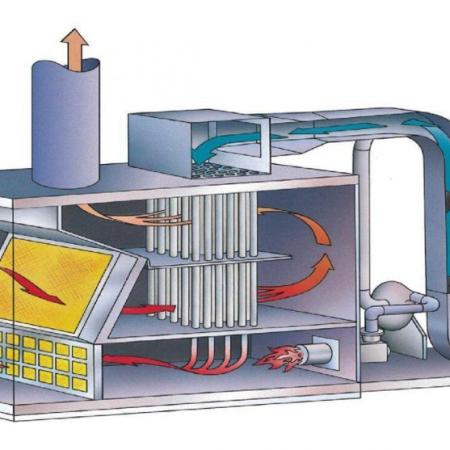

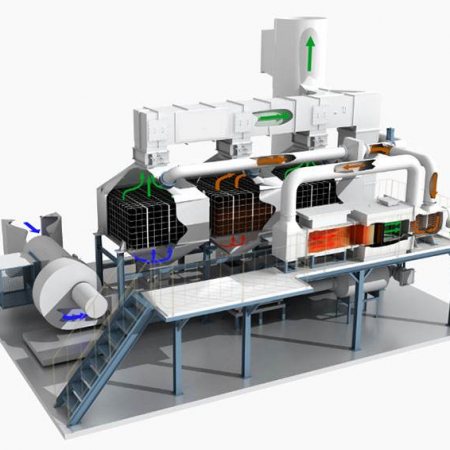

On the basis of learning from CO and RTO, RCO utilizes the principle that the energy required for the oxidation reaction of organic matter under the action of catalyst is far less than the energy required for direct combustion, and reduces the temperature of treating the organic waste gas from about 800 °C to 200-400 °C, which greatly saves energy consumption, and at the same time, the unique design of the efficient and advanced heat exchange system ensures the effective recovery of combustion heat.

Principle of RCO

The catalytic combustion process is carried out in a catalytic combustion unit. The hydrocarbons in the organic waste gas are rapidly oxidized into CO2 and H2O under the action of the catalyst at a relatively low ignition temperature to achieve the purpose of waste gas treatment. The organic waste gas is preheated to 200~400°C through the heat exchanger, and then enters the combustion chamber, and when passing through the catalyst bed, the hydrocarbon molecules and the oxygen molecules in the mixed gas are adsorbed on the surface of the catalyst and activated. Since surface adsorption reduces the activation energy of the reaction, hydrocarbons and oxygen molecules oxidize rapidly at lower temperatures, producing CO2 and H2O.

Advantages

1. The RCO catalytic combustion device is monitored by PLC control system during operation, which is easy to operate and can be fully automatic without manual control. Moreover, it greatly reduces the unstable factors of the catalytic combustion device in the process of operation, which is safe and reliable.

2. Using thermal cycle technology, the heat recovery rate is 285%, which not only saves energy, but also greatly reduces the operating cost.

3. Zhongcheng Lijing adopts superior technology, high-quality raw materials and advanced production equipment than the competitors, and the service life of the catalytic combustion device can be guaranteed to be more than 15 years.

4. The honeycomb ceramic carrier catalyst impregnated with precious metal of palladium and platinum is adopted, which has a large specific surface area, low resistance and high purification rate.

5. The purification efficiency of our catalytic combustion equipment is as high as 95% or more, and no secondary pollutants such as NOx are produced.

6. It occupies a small area, only 70%~80% of similar products in the same industry.

7. It only takes 15~30 minutes to start to heat up to the ignition temperature, and the energy is only consumed by the power of the fan, which automatically compensated when the concentration is low;

8. The safety protection measures meet the standards, and are equipped with automatic control systems such as flame retardant and dust removal systems, explosion-proof and pressure relief systems, and over-temperature alarming system.

Application

RCO equipment can be used in petroleum, chemical, plastic, rubber, pharmaceutical, printing, furniture, textile printing and dyeing, coating, painting, semiconductor manufacturing, synthetic materials and other industries, where producing medium and high concentration of large gas volume of organic waste gas, and can treat organic substances including benzene, phenols, aldehydes, ketones, ethers, esters, alcohols, hydrocarbons, etc.

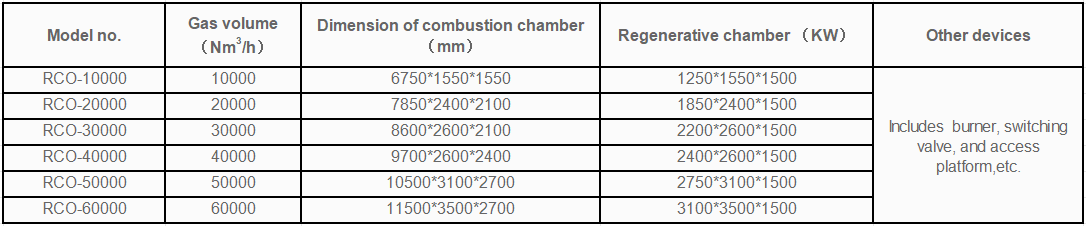

Technical Specification

Remarks:

Products with different air volumes can be customized according to customer requirements, and the actual specifications of the equipment are subject to the actual product.

Two or three chambers can be selected according to the customer's actual site conditions

Our engineering team can walk you through the design process and help you choose the suitable regenerative catalytic oxidizer that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms