Activated Carbon Adsorption Technology(ACAT)

Activated Carbon Adsorption Technology(ACAT)

Technical Principle of ACAT

Utilizing high-performance catalytic activated carbon, which has the following advantages:

(1) Catalytic activated carbon has a large adsorption space for target compounds;

(2) Catalytic activated carbon has a particularly strong ability to facilitate oxidation reaction, and in the adsorption process, catalytic activated carbon adsorbs H2S and oxygen on its surface, and oxidizes to generate more than 90% H2SO4 and a small amount of H2SO4 and S;

(3) After the catalytic activated carbon adsorbs odor gas, more than 90% of the resultant - H2SO4 is easily soluble in water. Based on this characteristic, when the catalytic activated carbon adsorption is saturated, the carbon bed can be washed with water, the resultant of H2SO4 can be dissolved and discharged from the carbon bed to achieve the purpose of regeneration, that is, the catalytic activated carbon bed can be repeatedly washed and regenerated, so it has the advantage of long life, and the regeneration is carried out inside the equipment, so the system can be fully automated.

Catalytic activated Carbon Oxidation Reaction Formula and Resultant Ratio Table

Oxidation reaction formula | % of resultant |

H2S+2O2→H2SO4 | >90% |

2H2S+3O2→2H2SO4 | >5% |

4H2S+O2→2H2S+2H2O+2H2O | <5%(among which the S content is minimal) |

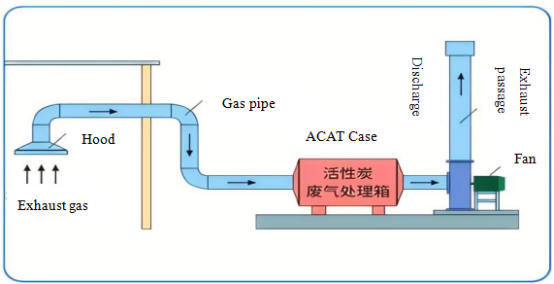

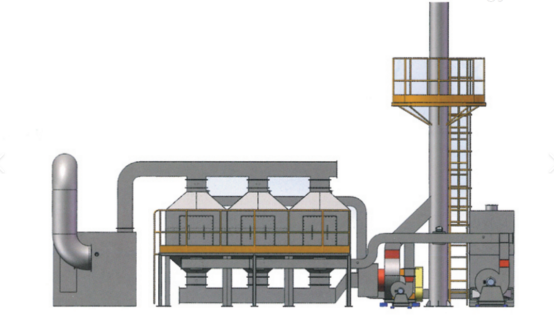

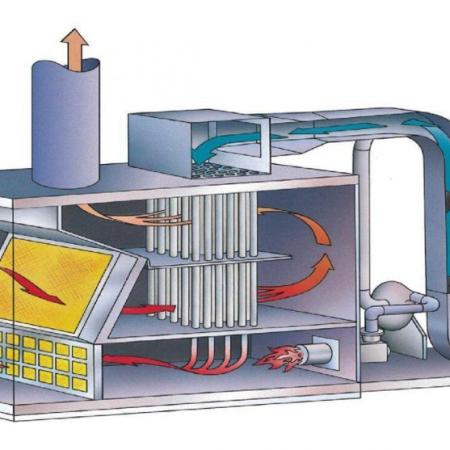

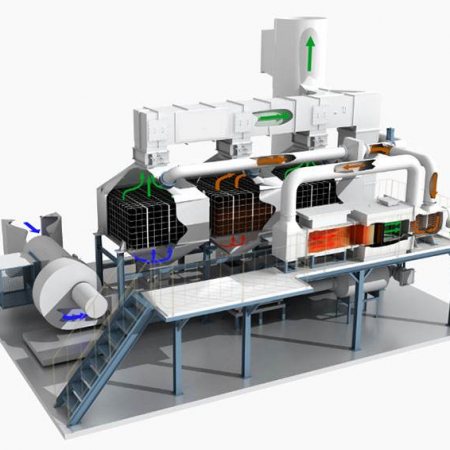

Process Description of ACAT

The suction port is arranged in the equipment or space where the exhaust gas is generated, the suction port and the exhaust gas purification device are connected through the pipeline. The exhaust gas is sent to the purification device through the centrifugal fan, and when it passes through the activated carbon layer, the exhaust gas will be adsorbed by the activated carbon, and the purified gas is discharged by the exhaust port of the equipment, so as to achieve the purpose of purifying the exhaust gas.

Process Features of ACAT

1) High deodorization efficiency, suitable for advanced deep treatment of exhaust gas.

2) Fully automatic regeneration, fundamentally avoid the problem of replacement;

3) Safe operation, not explosive due to chemical reaction and other reasons.

Application Scope of ACAT

ACAT is used fro organic and acid and alkaline gases produced in chemical industry, electronics, metallurgy, electroplating, chemical fiber, and food, or used in the rear segment of other exhaust gas purification technologies, for advanced treatment of exhaust gas and wastewater.

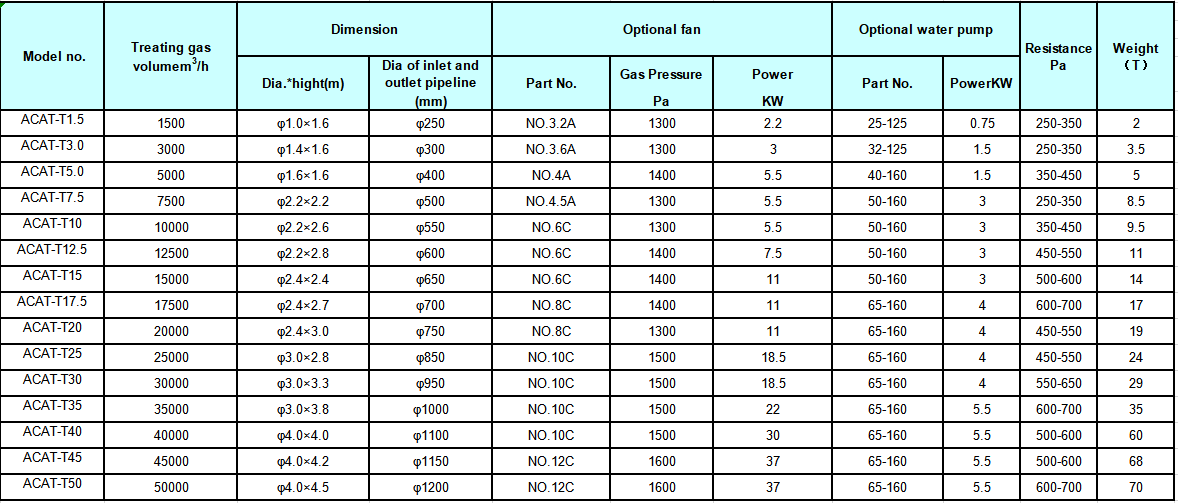

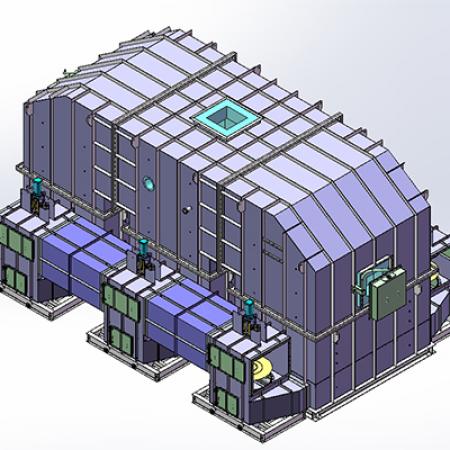

Selection Table of Activated Carbon Tower

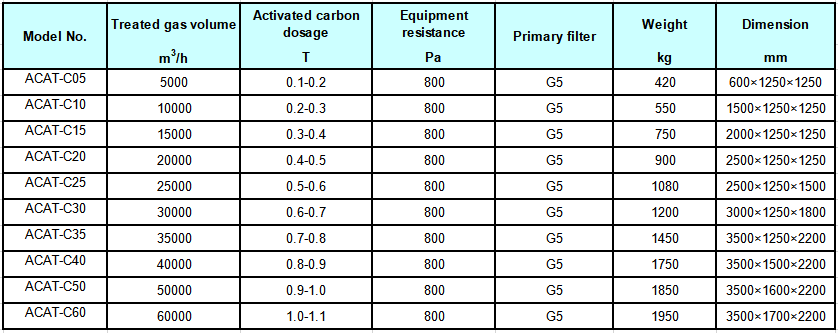

Selection Table of Activated Carbon Case

Our engineering team can walk you through the design process and help you choose the suitable activated carbon adsorption system that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms