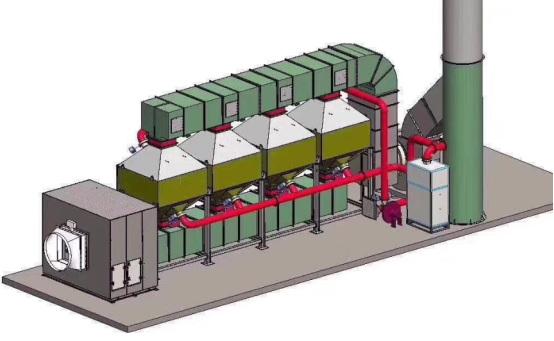

Catalytic Combustion(CO)

Catalytic Combustion(CO)

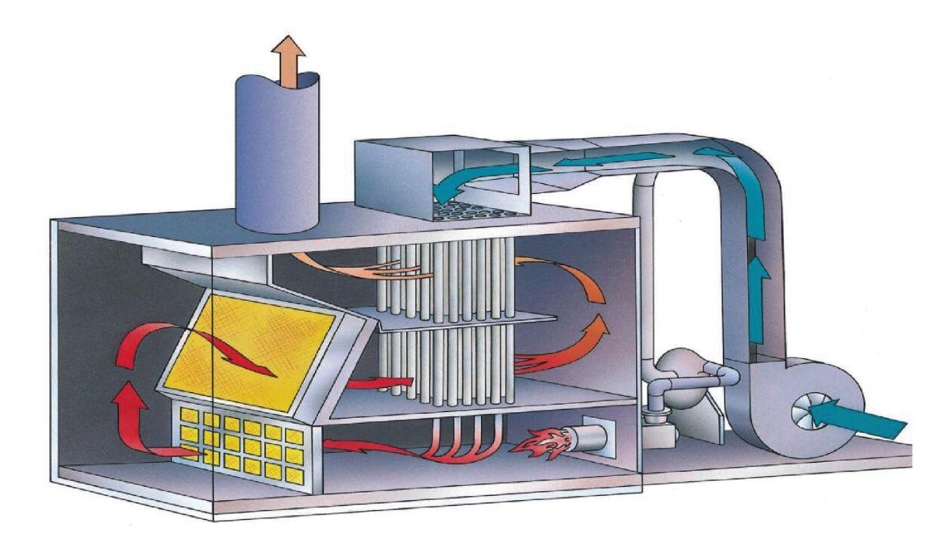

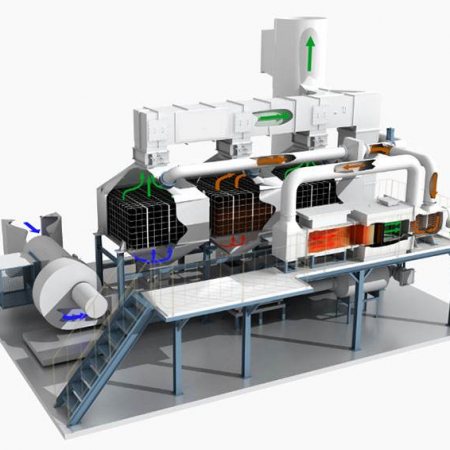

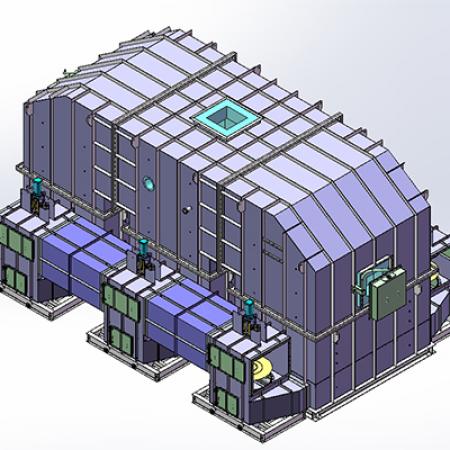

Principles of Catalytic Combustion

Catalytic combustion is an environmental protection equipment for the treatment of industrial waste gases containing VOCs (volatile organic compounds). The use of catalytic combustion technology can make organic waste gas produce flameless combustion at a relatively low ignition temperature (300-400°C), pyrolyzing pollutants into CO2 and H2O. The purification rate of industrial waste gas treated by catalytic combustion technology is generally more than 95%.

Catalyst

Catalytic combustion adopts a high-performance catalyst with a honeycomb ceramic carrier impregnated with precious metal of palladium and platinum, with high active site dispersion and high catalytic activity. The catalyst is generally replaced in 4 years, and the carrier is renewable, with long service life, little pressure loss and low overall energy consumption.

Compared with the traditional direct combustion, catalytic combustion has remarkable characteristics of low ignition temperature and low energy consumption. When the concentration of organic waste gas is high, self-heating can be realized, and external heating is no longer required after the ignition temperature is reached, and the operating energy consumption is only the power consumption of the fan.

Equipment Features

1. Easy to operate: it can realize automatic control when working.

2. Fast start-up and low energy consumption: it only takes 15-30 minutes for the equipment to heat up to the ignition temperature (when the concentration of organic waste gas is high, self-heating can be realized), and the operating energy consumption is only the power consumption of the fan itself.

3. Safe and reliable: the equipment is equipped with automatic control systems such as flame retardant and dust removal system, explosion-proof and pressure relief system, and over-temperature alarming system.

4. High purification efficiency: with the use of honeycomb ceramic carrier catalyst impregnated with precious metal of palladium and platinum, the purification efficiency can reach more than 95%.

5. Long service life: the catalyst is generally replaced once every 4 years, and the carrier is renewable.

Applications

It is suitable for the purification of high-concentration organic waste gas.

It is mainly used in petrochemical, electronics, automotive coating, painting, printing, rubber, chemical, furniture and other industries.

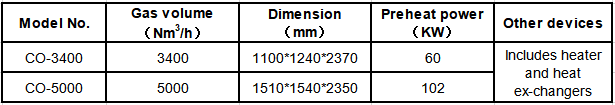

Technical Specification

Remarks: Products with different air volumes can be customized according to customer requirements, and the actual specifications of the equipment are subject to the actual application.

Our engineering team can walk you through the design process and help you choose the suitable catalytic combustion system that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms