Regenerative Thermal Oxidizer (RTO)

Regenerative Thermal Oxidizer (RTO)

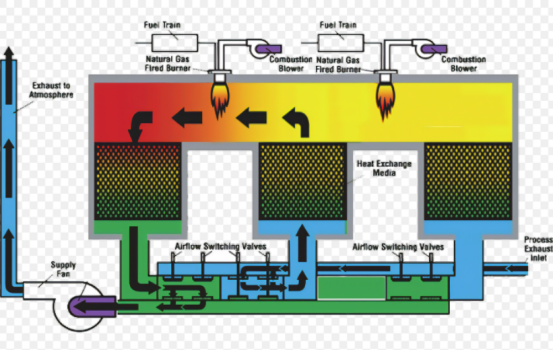

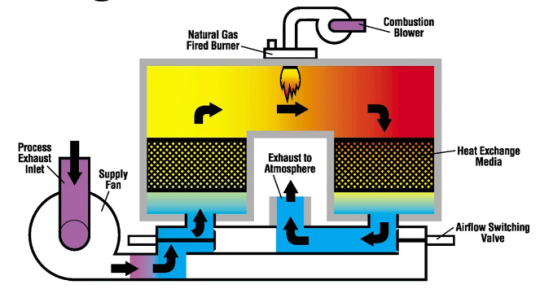

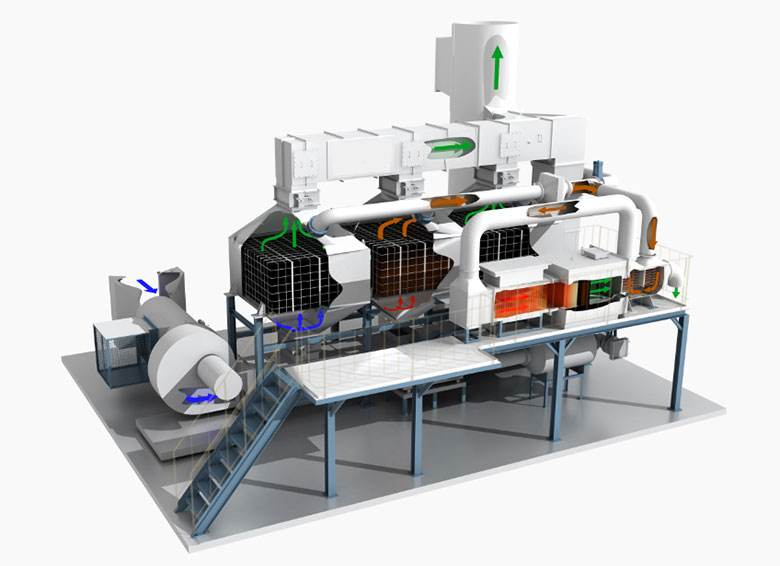

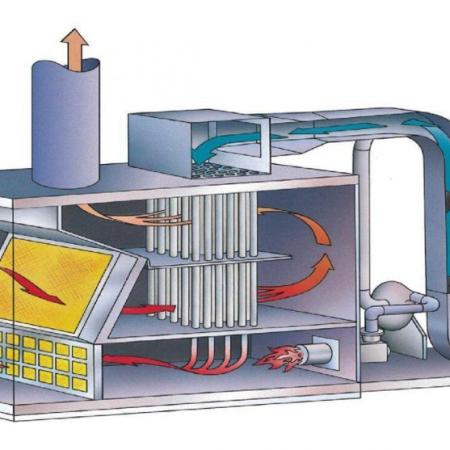

Principle of RTO

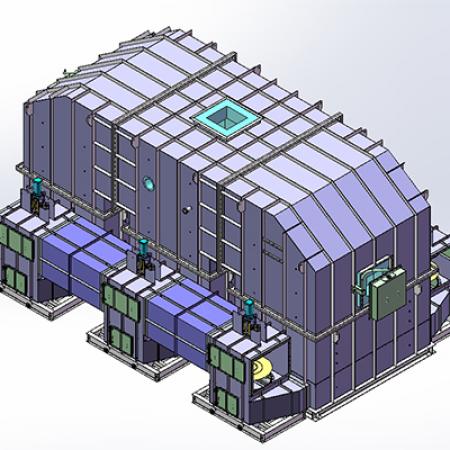

Regenerative thermal oxidizer is a kind of industrial waste gas treatment equipment, which heats the industrial waste gas containing VOCs (volatile organic compounds) to a temperature of more than 760 °C, thereby triggering thermal decomposition and decomposing it into CO2 and H2O, with a purification rate up to 99%. The rotary RTO is the latest design of the third generation, which is composed of a combustion chamber, a regenerative chamber and a burner, etc., and the purification rate can reach up to 99.6%, but it is not suitable for handling gases containing particles, heavy metals, inorganic gases, acids or other corrosive gases. Therefore, in practical applications, RTO equipment can be used in combination with dust removal equipment as appropriate.

Features

1. It can treat almost all exhaust gases containing organic compounds, and can adapt to changes and fluctuations in different concentrations.

2. The elasticity of the organic waste gas flow rate is large, which can be 60%-120% of the design gas volume.

3. It is not sensitive to small amount of dust and solid particles in the exhaust gas.

4. High thermal efficiency, reaching more than 95%.

5. Under the condition of suitable exhaust gas concentration, automatic self-heating operation can be realized without adding auxiliary fuel.

6. High purification rate (>99% for three chambers, >95% for two chambers).

7. Less maintenance workload, safe and reliable operation.

8. The device has a long service life.

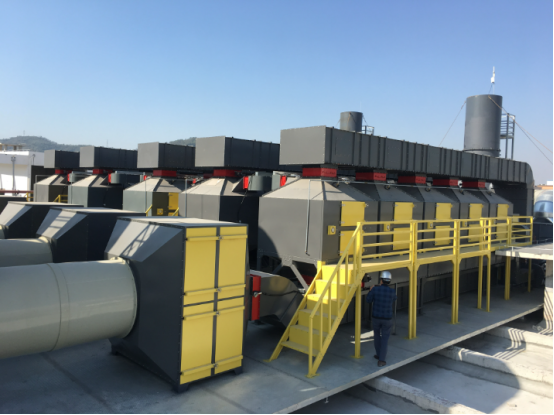

Applications

It is suitable for the purification of continuously discharged high-concentration organic waste gas, and is mainly used in petrochemical, construction machinery, automobile coating, painting, printing, rubber, chemical, furniture and other industries.

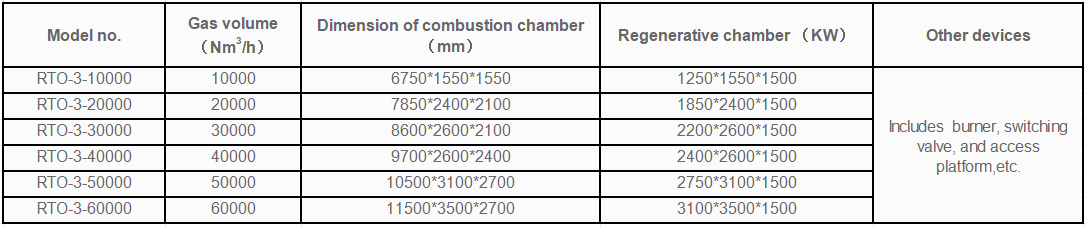

Technical Specification

Remarks:

Products with different air volumes can be customized according to customer requirements, and the actual specifications of the equipment are subject to the actual product. Two or three chambers can be selected according to the customer's actual site conditions

Our engineering team can walk you through the design process and help you choose the suitable regenerative thermal oxidizers that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms