Zeolite Molecular Sieve Wheel + CO Integrated system (ZMSW+CO)

Zeolite Molecular Sieve Wheel + CO Integrated system (ZMSW+CO)

( for treatment of large air volume and low concentration exhaust gas )

Overview

1.Zeolite Molecules

Zeolite molecule is a natural zeolite, which has the characteristics of high temperature resistance, corrosion resistance, high strength, non-flammability, and no secondary pollution, and the adsorption rate is 40% higher than that of similar activated carbons. This adsorbent material is first designed by the combination of silver and manganese to form a special structural effect, which can decompose ozone into reactive oxygen molecules, and then react with VOCs molecules to generate carbon dioxide and water. It is widely used in automotive spraying, coatings, printing, electronics, coal chemical industry, medicine and other industries.

2.Zeolite Molecular Sieve

It is a synthetic polyhydrous compound of crystalline silicate metal salt, compared with other adsorbents, zeolite molecular sieve has the following characteristics:

(1) It has strong adsorption capacity, the synthetic zeolite has small pores, many cavities, and large specific surface zone, and its adsorption capacity is significantly improved due to the superimposition of the force field around the cavity, and its adsorption capacity is still very large even if the adsorbent concentration is very low;

(2) It has high adsorption selectivity, ion exchange and catalysis, which can decompose ozone into reactive oxygen species atoms, and then react with VOCs molecules to generate carbon dioxide and water;

(3) Zeolite molecular sieve is a strong polar adsorbent, which has a strong affinity for polar molecules, especially water, and can also selectively adsorb unsaturated organic compounds. High thermal and chemical stability.

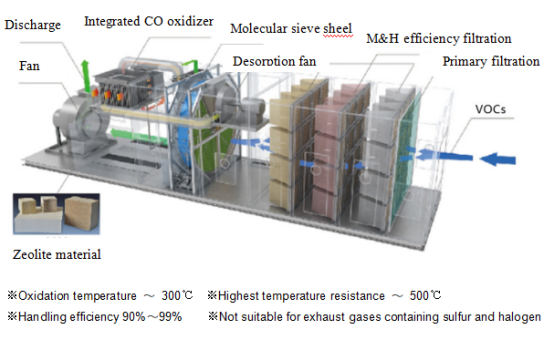

3. Zeolite molecular sieve wheel + CO integrated system (ZMSW+CO)

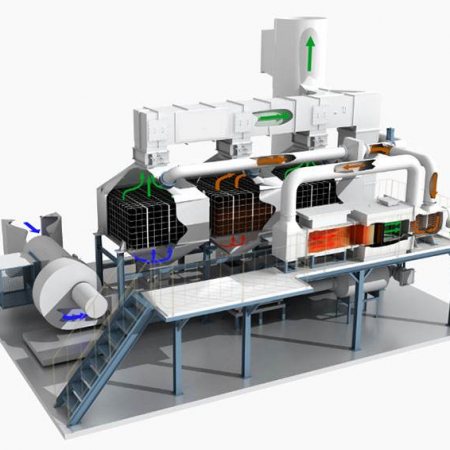

Zeolite molecular sieve wheel + CO catalytic combustion system is a new generation of treatment system designed for the current VOCs gas with a wide variety and different properties, which is often difficult to meet the emission requirements with one single purification technology. The system mainly combines the pre-treatment unit, the adsorption and concentration unit, and the thermal oxidation uni. It is a highly efficient organic exhaust gas treatment system with relatively complete prevention and control of VOCs.

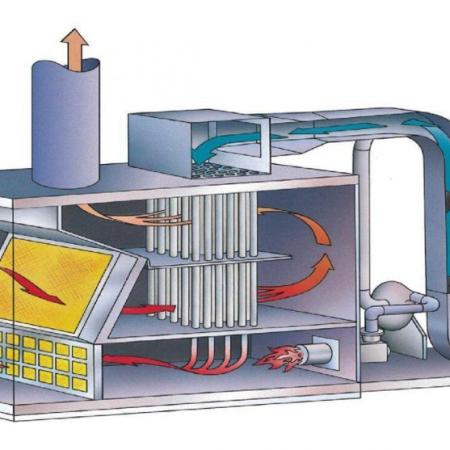

Working Principle of ZMSW+CO

The zeolite molecular sieve wheel adsorption and concentration system uses the continuous process of adsorption → desorption and concentration → cooling to adsorb and concentrate VOCs exhaust gas. The basic principle is as follows: ➀ The zeolite molecular sieve wheel is divided into three functional zones, the adsorption zone, the desorption zone and the cooling zone, and each zone is separated by heat-resistant and solvent-resistant sealing materials. The zeolite molecular sieve wheel runs continuously in various functional zones. ➁ After the exhaust gas passes through the pre-filter, it is sent to the adsorption zone (the zone of the adsorption zone is S1) where the VOCs in the organic exhaust gas are adsorbed and removed by the zeolite molecular sieve, and the organic exhaust gas is purified and discharged from the zeolite molecular sieve wheel treatment zone. ➂ VOCs adsorbed in the molecular sieve wheel are desorbed and concentrated in the desorption zone (the zone of the desorption zone is S2) after hot air treatment with a small air volume of about 200 ℃, and the concentration factor is generally 5~25 times. ➃ The regenerated zeolite molecular sieve wheel is cooled in the cooling zone. The air that passes through the cooling zone is heated and used as regenerative air to achieve the energy saving purpose.

Process Description

1) The organic exhaust gas is first removed by three layers of high-efficient dry filtration pre-treatment cabinets to remove 99% of the oily substances or dust and other particles in the exhaust gas, so as to prevent such substances from entering the zeolite wheel and causing blockage of molecular sieve.

2) After pre-treatment, the organic exhaust gas enters the adsorption zone of the zeolite wheel, the VOCs in the exhaust gas are adsorbed by the zeolite molecular sieve, and the purified gas is directly discharged up to the standard criteria, and the zeolite molecular sieve wheel that adsorbs VOCs rotates continuously (1-6 revolutions per hour) into the desorption zone, and then preheats to the desorption temperature of 180~220 °C by the heater under the action of the fan (it can also be preheated by discharging high-temperature gas through the catalytic bed), and the VOCs are desorbed from the zeolite to form a small volume of VOCs exhaust gas but with high concentration. After high temperature desorption, the wheel enters the cooling zone, and cools down (110 °C) under the action of the normal temperature gas of 1/25~1/15 of the original exhaust gas air volume to continue the circulation of adsorption;

3) The high-concentration tail gas produced by desorption enters the catalytic burner, and is preheated by the heat exchanger under the action of the system fan, then is heated to the catalyst reaction temperature (about 300 °C or 250 °C-350 °C) by the electric heater, and then oxidized and decomposed into carbon dioxide and water, and at the same time releases a large amount of heat, which is recovered and discharged after heat exchange with the zeolite wheel cooling gas and desorption gas in turn, and which greatly saves the heating energy consumption and realizes the purpose of high efficient energy saving and environmental protection.

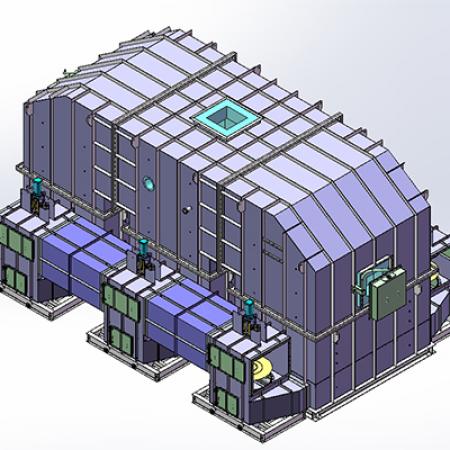

Module Composition

1.Air inlet module.

2.Surface cooler module (option).

3.Three-stage or four-stage filtration module.

4.Molecular sieve wheel module.

5.heat exchanger module.

6.Fan module.

7.CO /catalytic oxidation module.

8.Toolbox module (option).

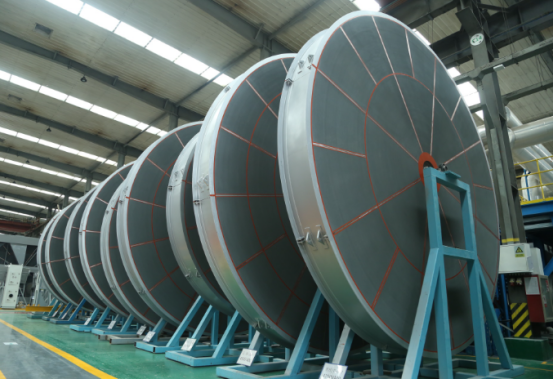

9.Structure of zeolite wheel adsorption and concentration device.

10. Exhaust gas pre-treatment system, molecular sieve wheel adsorption and concentration system, cooling and drying system, automatic control system, etc.

Technical Characteristics of ZMSW+CO

1.The concentration of pollutants discharged after purification is stable.

2.The single unit has a small footprint but large processing capacity.

3.Zeolite is non-combustible, and has high safety and stability.

4.It is easy to maintain and repair, and has a long service life.

5.Small pressure loss and low operating cost.

6.The system is equipped with perfect safety facilities and emergency measures to prevent the occurrence of explosion, fire, electric shock and other dangerous hazards.

7.The adsorbent material (zeolite molecular sieve) adopts modular installation, which is easy to maintain and manage.

8.The whole process of the system is controlled by PLC, which is simple to operate, low in operating cost and high in purification efficiency.

Scope of Application

It is widely used in automotive spraying, coatings, printing, rubber, electronics, semiconductors, coal chemicals, pharmaceuticals, lithium battery manufacturing and other industries.

●Exhaust treatment of various paint shops (automobile manufacturing, shipbuilding, bicycle manufacturing, aircraft manufacturing, metal products, etc.).

●Exhaust treatment of various printing workshops (gravure printing, building decoration material printing, and other printing processes).

●Exhaust treatment of aluminum profile production, coating processing technology, etc.

●Exhaust treatment of various electronic product manufacturing processes.

●Exhaust treatment of semiconductor integrated circuits and liquid crystal displays (LCD) manufacturing processes.

●Exhaust treatment of lithium-ion battery manufacturing process (electrode formation process, electrolyte filling process).

●Exhaust treatment in the production process of resin, rubber, tires and other products.

●Exhaust treatment of volatile organic compounds from dispersed sources such as automobile repair shops and clothing dry cleaners

Technical Parameter of ZMSW+CO

| Handling gas volume | Model no. | Dimension(mm) | Installed weight | Installed power | ||

| Nm3/h | L*W*H | t | Electric heating integrated device | Combustion integrated device | ||

| ELEC | ELEC KW | Gas Mcal | ||||

| KW | ||||||

| 5000 | ZMSW5K-MINI | 2000*1600*2850 | 2.7 | 24.7 | 9.7 | 150 |

| 10000 | ZMSW10K-MINI | 3455*2050*3550 | 5.4 | 44.7 | 14.7 | 150 |

| 15000 | ZMSW15K-MINI | 3470*2270*3850 | 6.6 | 63.7 | 18.7 | 150 |

| 20000 | ZMSW20K-MINI | 3470*2270*3850 | 7 | 78 | 23 | 150 |

| 20000 | ZMSW20K-ST-M | 9500*2750*3300 | 13 | 137 | 50 | 150 |

| ZMSW20K-ST-L | ||||||

| 30000 | ZMSW30K-ST-S | 9500*3050*3510 | 14 | 125 | 53 | 150 |

| ZMSW30K-ST-M | 144 | 57 | 150 | |||

| ZMSW30K-ST-L | 201 | 64 | 250 | |||

| 40000 | ZMSW40K-ST-S | 9500*3050*3510 | 14 | 162 | 75 | 150 |

| ZMSW40K-ST-M | 219 | 82 | 250 | |||

| ZMSW40K-ST-L | 287 | 90 | 250 | |||

| 50000 | ZMSW50K-ST-S | 10700*3950*4585 | 18.5 | 182 | 95 | 150 |

| ZMSW50K-ST-M | 239 | 102 | 250 | |||

| ZMSW50K-ST-L | 307 | 110 | 300 | |||

| 60000 | ZMSW60K-PLUS-S | 10700*3950*4585 | 18.5 | 236 | 98.5 | 150 |

| ZMSW60K-PLUS-M | 307 | 110 | 250 | |||

| ZMSW60K-PLUS-L | 347 | 118 | 400 | |||

| 70000 | ZMSW70K-PLUS-S | 13000*4390*4800 | 25 | 254 | 117 | 250 |

| ZMSW70K-PLUS-M | 322 | 125 | 250 | |||

| ZMSW70K-PLUS-L | 497 | 142.5 | 500 | |||

| 80000 | ZMSW80K-PLUS-S | 13000*4390*4800 | 25 | 254 | 117 | 250 |

| ZMSW80K-PLUS-M | 389 | 133 | 400 | |||

| ZMSW80K-PLUS-L | 497 | 142.5 | 500 | |||

| 90000 | ZMSW90K-PLUS-S | 13000*4950*5350 | 28 | 342 | 145 | 250 |

| ZMSW90K-PLUS-M | 409 | 153 | 400 | |||

| ZMSW90K-PLUS-L | 577 | 172.5 | 600 | |||

| 70000 | ZMSW100K-PLUS-S | 13200*4950*5350 | 28 | 364 | 167 | 250 |

Our engineering team can walk you through the design process and help you choose the suitable zeolite molecular sieve wheel + CO integrated system (ZMSW+CO) that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms