UV Photo-oxygen Catalytic Purification Equipment(UVPOC)

UV Photo-oxygen Catalytic Purification Equipment(UVPOC)

Overview

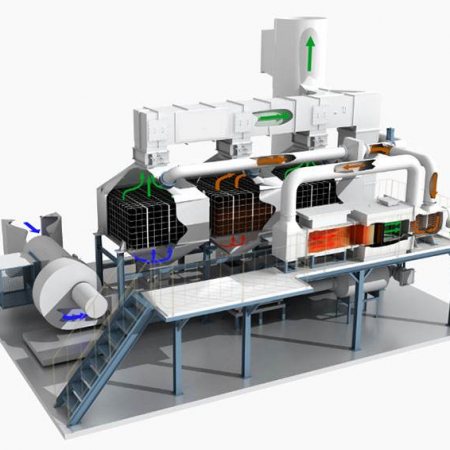

The UV purifier has high efficiency of deodorization: it can efficiently remove major pollutants such as organic VOC, inorganics, hydrogen sulfide, ammonia, mercaptans, as well as various odors, with a deodorization efficiency of more than 99.9%.

Product features: compact equipment structure, low investment, easy operation. The UV purifier is made of standard materials or stainless steels, and the air volume is 6000-60000m³/h. The above is the current advanced equipment for the treatment of industrial organic exhaust gas pollution.

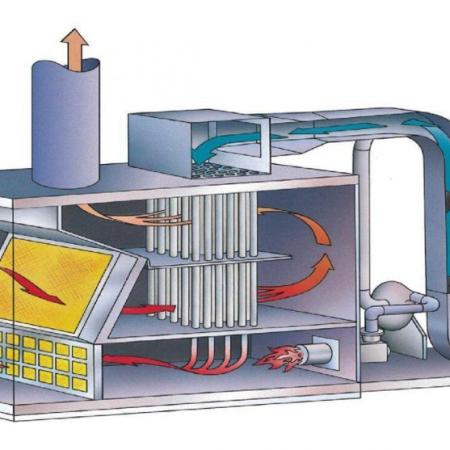

Working Principle of UVPOC

The high-energy UV beam is used to crack the molecular bonds of bacteria in the odorous gas to produce free radicals, destroy the nucleic acid (DNA) of bacteria, and carry out oxidation reaction through ozone to completely achieve the purpose of deodorization and killing bacteria.

The high-energy UV beam is used to decompose the oxygen molecules in the air to produce free oxygen, that is, reactive oxygen species, which needs to be combined with oxygen molecules due to the imbalance of positive and negative electrons carried by free oxygen, and then produce ozone.

UV decomposes oxygen to produce reactive oxygen species, which combines with oxygen molecules to produce ozone, which has a strong oxidizing effect on organic matter and has an immediate removal effect on odorous gases and other irritating odors.

The nano-photocatalyst of TiQ2 is stimulated to generate a kind of high-energy particles (electron-hole pairs) under the irradiation of a specific wavelength of light, which has a strong oxidation-reduction ability after the interaction with the surrounding water/oxygen, which can directly decompose pollutants such as aldehydes and hydrocarbons in the air into harmless and odorless substances, as well as destroy the cell wall of bacteria, and kill and decompose their bacteria, so as to achieve the purpose of eliminating air pollution.

After the odorous gas is input into the purification equipment by exhaust air collecting equipment, the purification equipment combines the technologies of high-energy UV ultraviolet beam/ozone O3 and nano photocatalytic TiQ2 to carry out synergistic decomposition and oxidation reaction on the exhaust gas, so that the exhaust gas is degraded and converted into harmless and odorless compounds/water and carbon dioxide, and then discharged through the exhaust pipe.

Advantage of UVPOC purification equipment

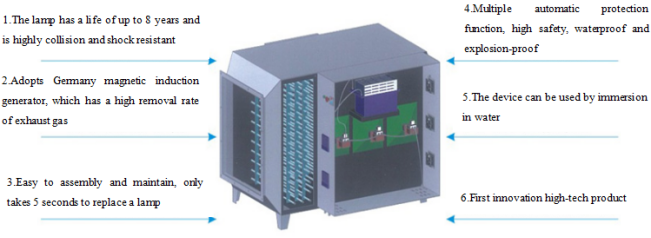

Performance advantages of magnetic induction UVPOC purification equipment

1. Efficient deodorization: it can efficiently remove major pollutants such as volatile organic compounds (VOCs), inorganic substances, hydrogen sulfide, ammonia, mercaptans, etc., as well as various odors, with a deodorization efficiency of more than 99%.

2. No need to add any substances: only need to set up the corresponding exhaust pipe and exhaust power, so that the odor/industrial exhaust gas can be deodorized and decomposed and purified through this equipment, no need to add any substances to participate in the chemical reaction. The oxidation reaction and chemical reaction are carried out at room temperature and pressure, and there is no secondary pollution.

3. Strong adaptability: high-efficient UVPOC purification equipment can adapt to the deodorization and purification treatment of high concentration, large atmospheric volume, and different industrial exhaust gas substances, and can work continuously 24 hours a day, with stable and reliable operation.

4. Low operating cost: high-efficient UVPOC purification equipment has no mechanical action, no noise, no need for special management and daily maintenance, only need to do regular inspection, the energy consumption is low, the wind resistance of the UVPOC equipment is very low as <50pa, which can save a lot of exhaust power energy consumption,which is only 0.001Kw/m3 on the average.

5. The UVPOC equipment occupies a small area and is light in weight: it is suitable for special conditions such as compact and narrow site, and the equipment covers an area of <1.2 square meters for each processing of 10,000m3/h air volume.

6. Manufacture of high-quality stainless steels: fireproof and anti-corrosion with high energy, safe and stable equipment performance, and the service life of the UVPOC equipment is more than 15 years.

7. High-tech patented products of environmental protection: using the most advanced technology concept in the world, through the long-term repeated tests of experts and our company's engineering and technical personnel, the high-tech environmental protection purification products with completely independent intellectual property rights can completely decompose toxic and harmful substances in the industrial exhaust gas, and can achieve perfect deodorization and purification effect.

8. Explosion-proof certification products: the UVPOC equipment has safety and explosion-proof characteristics, and has passed the EX explosion-proof qualification certification of the National Explosion-proof Electrical Product Quality Supervision and Inspection Center (certificate number CNEx13.0829X), which can be widely used in oil (gas) fields, petrochemical, pharmaceutical and other industries with high explosion-proof requirements.

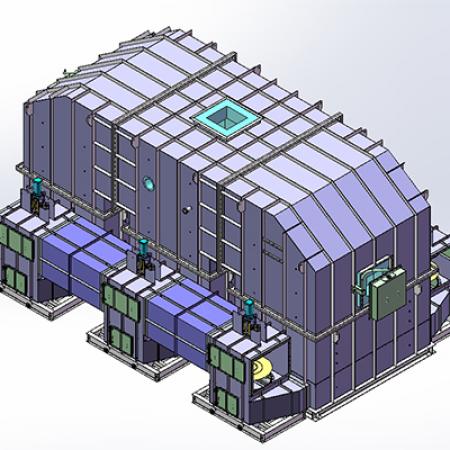

Technical Parameter of UVPOC

Model No. | Dimension (L*W*H) | Configurations | Voltage | Power | Size of air inlet and outlet (mm) | Mat. of main frame |

UV-5000 | 1200*900*900 | 2 sets of electric fields, 1 set of high-frequency low-temperature plasma power supply. 1 set of electric control box, automatic current protection device, temperature sensing controller, air inlet and outlet air filter | AC 220V | 0.6KW | 500*600 | Brushed stainless steel |

UV-10000 | 1200*1100*1000 | 2 sets of electric fields, 2 set of high-frequency low-temperature plasma power supply. 1 set of electric control box, automatic current protection device, temperature sensing controller, air inlet and outlet air filter | AC 220V | 1.6KW | 700*700 | Brushed stainless steel |

UV-15000 | 1700*1300*1300 | 8 sets of electric fields, 4 set of high-frequency low-temperature plasma power supply. 1 set of electric control box, automatic current protection device, temperature sensing controller, air inlet and outlet air filter | AC 220V | 2.4KW | 900*1000 | Brushed stainless steel |

UV-20000 | 1700*1500*1500 | 8 sets of electric fields, 4 set of high-frequency low-temperature plasma power supply. 1 set of electric control box, automatic current protection device, temperature sensing controller, air inlet and outlet air filter | AC 220V | 3.2KW | 1100*1200 | Brushed stainless steel |

UV-30000 | 2800*1600*1600 | 12 sets of electric fields, 6 sets of high-frequency low-temperature plasma power supply. 1 set of electric control box, automatic current protection device, temperature sensing controller, air inlet and outlet air filter | AC 220V | 3.6KW | 1200*1300 | Brushed stainless steel |

UV-40000 | 2800×1950×1700 | 12 sets of electric fields, 6 sets of high-frequency low-temperature plasma power supply. 1 set of electric control box, automatic current protection device, temperature sensing controller, air inlet and outlet air filter | AC 220V | 4.8KW | 1550*1400 | Brushed stainless steel |

Our engineering team can walk you through the design process and help you choose the suitable UV photo-oxygen catalytic purification equipment(UVPOC) that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms