Desulfurization

Desulfurization

Overview

Air SO2 pollution is very serious in many cities, there are 62% of the average concentration of SO2 in the urban environment air exceeds the secondary standard of the national ambient air quality standard, daily average concentration exceeds level 3rd standard. Now most of the lands are facing the acid rain pollution problem caused by the large amount of SO2 emissions. The desulfurization and denitration are extremely in need to purify the SO2 contained flue gas, to protect our land, air and people’s health.

Classification of Desulfurization

Currently there are two methods to conduct the desulfurization:

1. Wet method of desulfurization technology

2. Dry method of desulfurization technology

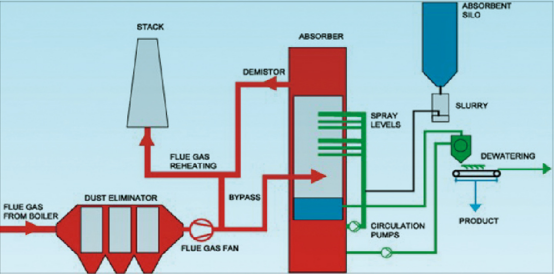

Desulfurization Process Flow Chart of Wet Method

Features

1. It has a wide range of applications, and is not limited by the sulfur content of coal and boiler capacity.

2. The desulfurization efficiency is very high, and it is easy to reach more than 95%. After desulfurization, the flue gas not only has a very low sulfur dioxide concentration, but also the dust content of the flue gas is greatly reduced.

3. The absorbent is easy to purchase, and can be in three forms: liquid ammonia, ammonia, and ammonium carbonate.

4. The ammonia desulfurization device has strong adaptability to the load change of the unit, and can adapt to the methods of fast start, cold start, temperature start, hot start, etc. It adapts to the operation of the unit load under the condition of 35%BMCR~100%BMCR.

5. The equipment is reliable and has a long service life.

6. Ammonia is a good alkaline absorbent, and the utilization rate of absorbent is very high.

7. The liquid-gas ratio is low, and the operating power of the rotating equipment is low.

8. Good environmental benefits.

9. Ammonium sulfite has a high oxidation rate, ammonium sulfate product has a high recovery rate and pure quality.

10. The flue gas desulfurization system has less resistance and low operating cost.

11. High efficiency of flue gas desulfurization and ammonium sulfate recovery.

Our engineering team can walk you through the design process and help you choose the suitable flue gas desulfurization system that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms