Denitration

Denitration

Overview

Air SO2 pollution is very serious in many cities, there are 62% of the average concentration of SO2 in the urban environment air exceeds the secondary standard of the national ambient air quality standard, daily average concentration exceeds level 3rd standard. Now most of the lands are facing the acid rain pollution problem caused by the large amount of SO2 emissions. The desulfurization and denitration are extremely in need to purify the SO2 contained flue gas, to protect our land, air and people’s health.

Classification of Denitration

Currently there are two methods to conduct the denitration:

1. Selective catalytic reduction(SCR)

2. Selective non-catalytic reduction(SNCR)

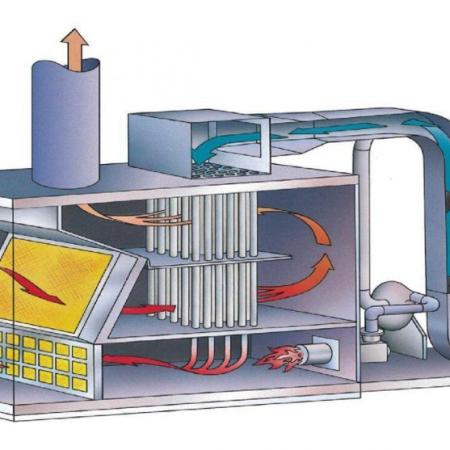

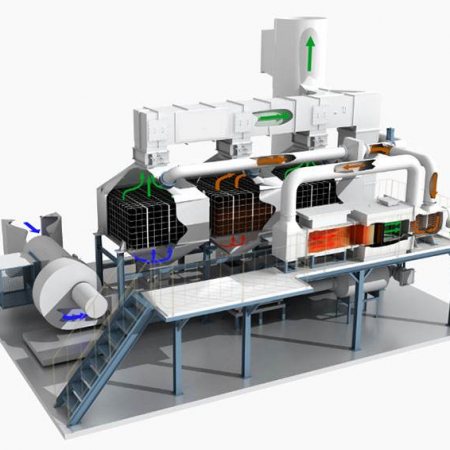

Working Principle

Selective catalytic reduction mathod referred to as “SCR”, which means to selectively act with nitrogen oxide in flue gas and generate a non-toxic pollution-free nitrogen and water, with liquid ammonia or urea as a reducer, under certain temperature and catalyst. The technology can use liquid ammonia or urea as the denitration reducer.

SCR denitration technology uses nitrogen oxides catalyst reduction reaction, the reaction temperature is as low as 300~450℃. The method is to spray the reducer into the reactor with catalyst, and the flue gas will make chemical reaction with the reducer through the catalyst, thus realizing the purpose of denitration.

SCR denitration technology is the most matured method to conduct the denitration. It is mainly used at the downstream of the flue gas of solid or liquid slag discharge boilers in coal-fired and kerosene power plants. At a certain temperature and in the presence of a catalyst, NH3 or urea as a reducing agent is introduced into the flue gas to reduce the NOx in the flue gas to harmless nitrogen (N2) and water (H2O), so as to achieve the purpose of removing NOX, purifying the flue gas and reducing the pollutant emission of the power plant.

The main chemical reaction equation is as follows:

4NO+4NH3+Q2→6H2O+4N2

NO+NO2+2NH3→3H2O+2N2

6NO2+8NH3→7N2+12H2O

Features

● The denitration efficiency is as high as more than 90%.

● Ammonia escape concentration at the outlet is low, fully meeting the national standard.

● SO2 to SO3 conversion rate is as low as less than 1%.

● Honeycomb or plate type catalyst design, ensure the max catalyst surface area.

● Special even distribution of flue gas and reducer , ensure good denitration efficiency.

● The reactor can be put between the economizer and air preheater, or after the desulfurization tower

● Two options to provide the ammonia or liquid NH3 to meet different needs.

● Small system resistance, less than 1000pa.

● Adapt to the temperature range from 160~510℃.

Application

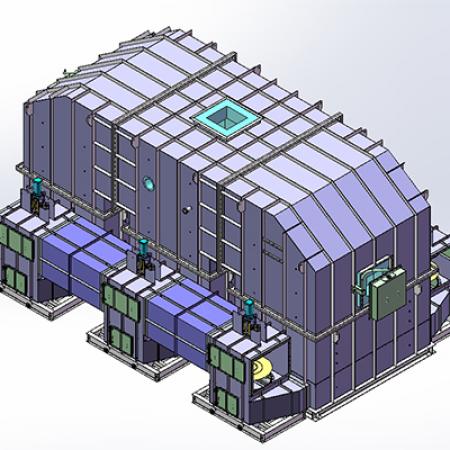

SCR denitration technology is mainly used for flue gas denitration for caol-fired boiler, cogeneration boiler,centralized heating boiler, incinerator, sinter and pellet kiln, coking furnace, glass furnace, ceramic kiln and furnace, etc.

Our engineering team can walk you through the design process and help you choose the suitable flue gas denitration system that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms