Bio-filtration Pool Deodorization Technology (BFPD)

Bio-filtration Pool Deodorization Technology (BFPD)

Overview

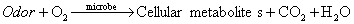

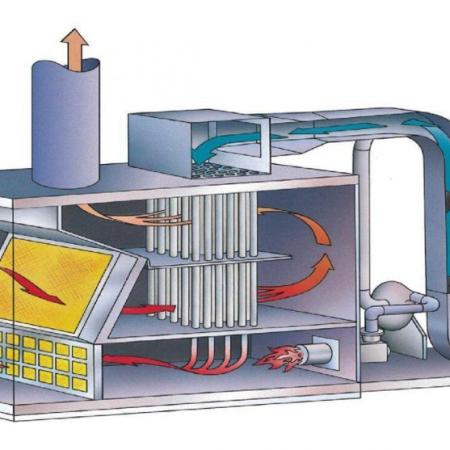

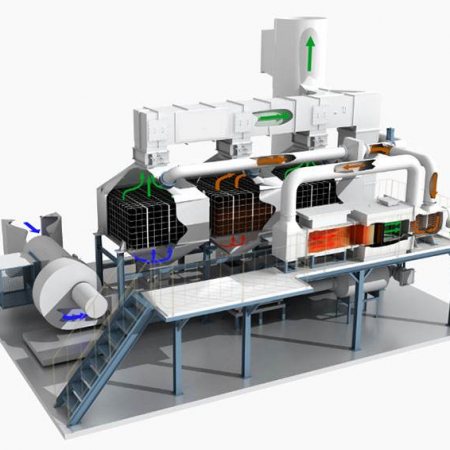

Bio-filtration pool deodorization technology is a treatment system, which converts odorous substances into non-toxic CO2, H2O, H2SO4, NHO3 and other simple inorganic substances after adsorption and absorption by microorganisms on a certain proportion of prepared active biological media, through the adsorption, absorption and degradation of odorous substances by microorganisms.

Active biological media have a large porosity and specific surface area and are maintained at a certain humidity by controlled circulating spraying. The medium carries a large number of domesticated organisms (biochemical compounds composed of fungi and bacteria). The odor comes into contact with the water in the medium during its passage through the bed of biological active media, in which it produces an adsorption effect and dissolves into the water film on the medium. Microorganisms active in the medium are metabolized by adsorption and absorption of ingredients in the odor under suitable temperature and humidity conditions. In the process of microbial metabolism, odorous ingredients are decomposed by microorganisms as nutrients to produce harmless substances such as CO2 and H2O, so that pollutants can be removed.

The bio-filtration pool deodorization system is one of the most energy-efficient systems in the world for the treatment of harmful gases such as volatiles organic compounds (VOCs) and H2S. It is also the most researched, mature technology, and the most commonly used method to deal with odorous gases in practice. The treatment process is that after the pre-treatment process such as dust removal, humidification or cooling, the gas containing odorous substances passes through the filter bed from the BFPDtom to the top, and the odorous substances are transferred from the gas phase to the water-microbial mixed phase (biological layer) when passing through the filter layer, and are decomposed by the metabolism of the microorganisms attached to the filter material. It can be simplified to the following expression:

Technical Characteristics of PFPD

1. Chongqing University and Chongqing Academy of Environmental Sciences provides technical support for strain cultivation.

2. There is no need for high-cost chemicals, and the operation is stable, and high resistance to load impact.

3. Appropriate microorganisms are made for specific harmful gas ingredients to improve the load rate per unit volume.

4. Special ratio of active medium, large specific surface area, high porosity, can support a large number of microorganisms.

5. The pressure loss of the active medium is small, which can reduce energy consumption and operating costs.

6. Natural bio-degradation is used to decompose pollutants into CO2 and H2O, and no secondary pollutants are generated.

7. The VOC removal rate is high, and the removal rate of H2S can exceed 99%.

8. The PLC control system is fully automatic, without personnel management.

Technical Parameters of Low-concentration Deodorization System

Part No. | Treating Capacity m3/hr | Dimension (m) | Pressure Loss Pa | Water content m3/d | ||

L | W | H | ||||

BFPD-L3000 | 1000~3000 | 4.5 | 3.0 | 3.0 | 200~400 | 4.5 |

BFPD-L5000 | 3000~5000 | 7.0 | 3.0 | 3.0 | 200~400 | 7.5 |

BFPD-L7000 | 5000~7000 | 8.5 | 3.0 | 3.0 | 200~400 | 10.3 |

BFPD-L9000 | 7000~9000 | 11.0 | 3.6 | 3.0 | 200~400 | 13.5 |

BFPD-L11000 | 9000~11000 | 13.0 | 3.6 | 3.0 | 200~400 | 16.5 |

BFPD-L13000 | 11000~13000 | 9.5 | 3.0×2 | 3.0 | 200~400 | 19.5 |

Remark:

1. The determination of fan pressure requires a detailed calculation of the air duct loss.

2. The equipment suitable for the odor concentration of hydrogen sulfide of 5~20mg/m3, and ammonia of 2~5mg/m3.

Technical Parameters of Medium and High Concentration Deodorization System

Part No. | Treating Capacity m3/hr | Dimension (m) | Pressure Loss Pa | Water content m3/d | ||

L | W | H | ||||

BFPD-MH3000 | 1000~3000 | 5.5 | 3.0 | 3.0 | 200~400 | 6.0 |

BFPD-MH5000 | 3000~5000 | 9.0 | 3.0 | 3.0 | 200~400 | 10.0 |

BFPD-MH7000 | 5000~7000 | 10.5 | 3.6 | 3.0 | 200~400 | 14.0 |

BFPD-MH9000 | 7000~9000 | 13.0 | 3.6 | 3.0 | 200~400 | 18.0 |

BFPD-MH11000 | 9000~11000 | 10.0 | 3.0×2 | 3.0 | 200~400 | 22.0 |

BFPD-MH13000 | 11000~13000 | 11.5 | 3.0×2 | 3.0 | 200~400 | 26.0 |

Remark:

1. The determination of fan pressure requires a detailed calculation of the air duct loss.

2. The equipment suitable for the odor concentration of hydrogen sulfide of 20~60mg/m3, and ammonia of 5~30mg/m3.

In addition: the odor treatment plan under special circumstances is determined, please contact our company. Our company's technical personnel will assist in making corresponding technical treatment plans for odor collection and treatment systems.

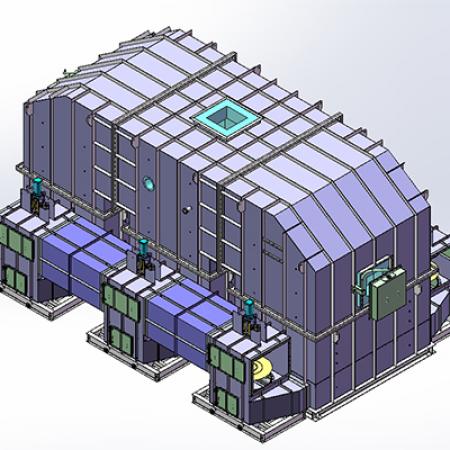

Advantages of Closed Engineering

1. The fluorocarbon fiber membrane with strong corrosion resistance is used to cover the exhaust gas, and the steel structure hangs the membrane outside. This not only exerts the corrosion resistance of the fluorocarbon fiber membrane, but also fundamentally solves the corrosion problem caused by the contact between the steel structure and the corrosive gas.

2. Due to the light weight of the membrane material and the high tensile strength, the membrane structure can fundamentally overcome the difficulties encountered by the traditional structure in the realization of large-span (no support in the middle) building, and is suitable for large-span pools.

3. Because all the steel support anti-hanging film structures are sealed and the membrane structure is shaped with a smooth curved surface (negative Gaussian surface), the wind load carrier type is small and the wind resistance level is high, which can be designed to resist typhoons of grade 12.

4. Quick installation: the steel structure production and membrane processing are carried out in the factory, and the processing quality is reliably guaranteed. The on-site installation time is short, which reduces the occupation of the site, especially the old pool renovation project can be hoisted as a whole without affecting the operation of the equipment inside the pool.

5. Good sealing performance: all membranes are hot-melt welded, and the "secondary node seal" of on-site hot-melt welding is used between the membrane pieces installed on site not only to ensure the sealing of the cover body, but also to ensure the corrosion of the steel structure by internal corrosive gas.

6. Beautiful appearance: the steel support anti-hanging membrane structure has all the characteristics of modern architecture-membrane structure; The shape is elegant and beautiful, and the self-cleaning performance is good.

Our engineering team can walk you through the design process and help you choose the suitable system of bio-filtration pool deodorization technology (BFPD) that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms