Biological Oxidation Deodorization Technology (BODT)

Biological Oxidation Deodorization Technology (BODT)

Working Principles:

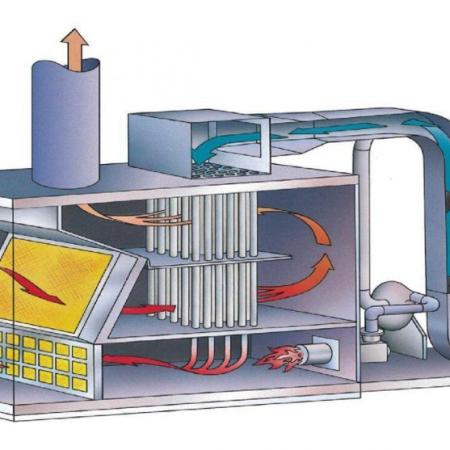

Biological oxidation deodorization technology, also known as "microbial" degradation technology, utilizes a combination of liquid absorption and biological treatment, and utilizes deodorizing microorganisms growing on the filter material to degrade the main odorogens, such as H2S, SO3 and most volatile organic compounds, with a deodorization efficiency of up to 98-99%.

The main process is as follows: first the hanging film of special microbial flora is cultivated on the filler materials, when the polluted gas passes through the surface of the filler materials, the microbial flora that can obtain the nutrient source from the polluted gas will be rapidly grown and reproduced under the conditions of suitable temperature, humidity, PH value, etc., and form a biofilm on the surface of the filler material. When the odor passes through the biofilm, the organic matter is adsorbed and degraded by the microorganisms on the surface of it .

The essence of pollutant removal is to use odor as nutrients to be absorbed, metabolized and utilized by microorganisms. This process is a coordinated process of microorganisms, which is relatively complex, and it is composed of physical, chemical, physicochemical and biochemical reactions.

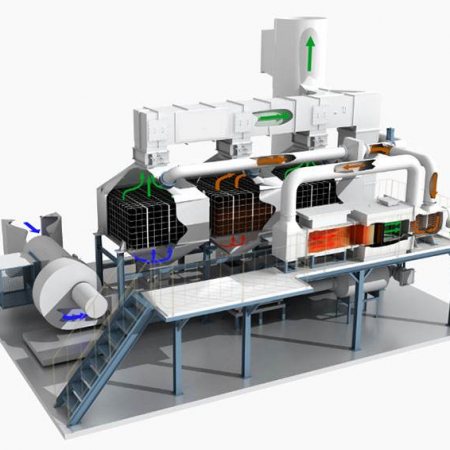

Process description of BODT

The microbial deodorization process is divided into three steps:

(1) The odor comes into contact with the water and dissolves into it.

(2) The odorous ingredients in the water solution are adsorbed and absorbed by microorganisms, and the odorous ingredients are transferred from the water to the microorganisms.

(3) The foul-smelling ingredients that enter the cells of microorganisms are decomposed and utilized by microorganisms as nutrients, so that pollutants can be removed.

Process characteristics of BODT

● Green and environmentally friendly: no harmful chemicals are used, energy demand is low, and no secondary pollutants are produced (only a small amount of sewage is produced, but the water quality is benign).

● High treatment efficiency: with the use of high-efficiency biological strains, the removal effect is obvious, and the removal rate of the main odorous gas reaches more than 98%.

● Saving labor costs: it can be fully automatically operated by the upper computer in the central control room or regularly inspected twice a day, and the whole system runs smoothly under unattended conditions.

● Easy maintenance: the whole system is reasonably designed and carefully considered, which greatly reduces the difficulty of maintenance and makes the whole system more user-friendly.

function of intermittent work: the effect of running again after stopping work for 10-15 days will not be affected.

Scope of Application of BODT

(1) Municipal industries such as sewage, sludge, garbage, and fecal treatment;

(2) Exhaust gas generated by industrial production (paper mills, printing and dyeing factories, pharmaceutical factories, petrochemical plants)

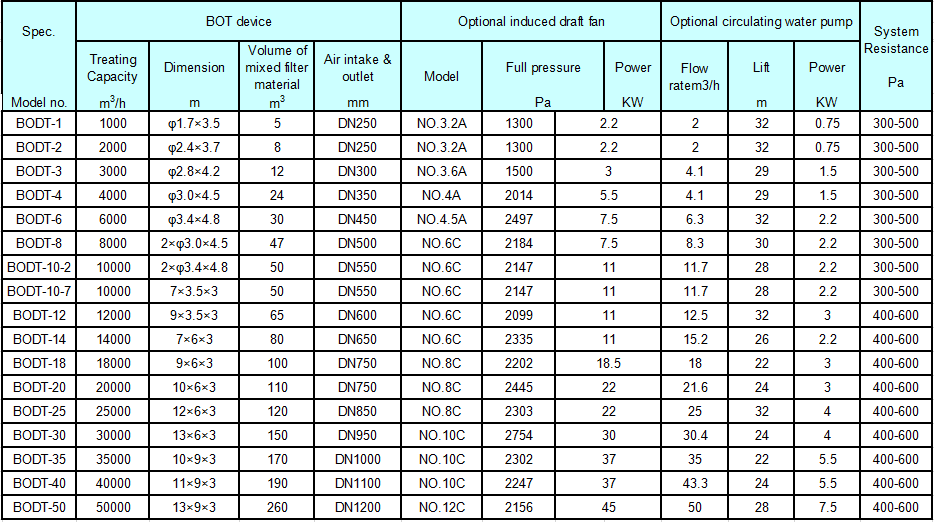

Selection Table of BODT Equipment

Our engineering team can walk you through the design process and help you choose the suitable system of biological oxidation deodorization technology that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms