Horizontal Sand Mill

Horizontal Sand Mill

Overview

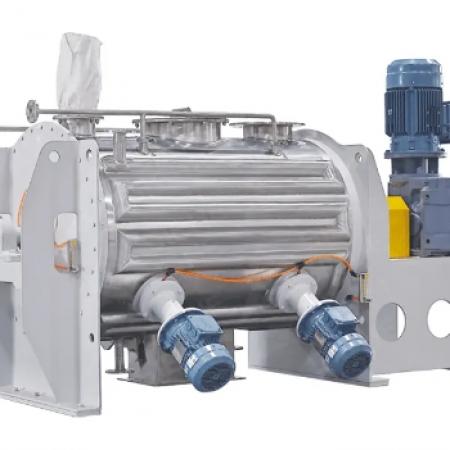

Nano grinding is our focusing area, and the perfect automation solution is our important working goal. Horizontal sand mill is also known as horizontal bead mill. When in operation, the slurry after pre-dispersion and wetting treatment is sent from bottom up to the grinding tank by the feeding pump, and the grinding beads will fall downward because of the specific gravity, so that the raw materials will form an up and down convection in the grinding tank under pressure. The raw materials will be emulsified, dispersed, kneaded and ground between the grinding beads, through pressurization, high-speed rotation and interactive impact, then, the required fineness can be quickly achieved. After grinding, the qualified parts will then be transported out of the grinding tank by the high-speed rotating tungsten steel separation gap. All the above process forms a complete grinding cycle, and with continuous cycles, the grinding fineness can reach less than 5um.

Horizontal sand mill, as a kind of high-efficiency grinding machinery, is widely used for wet stirring, ultra-fine grinding and dispersing the solid and liquid materials in non-metallic industries, such as coatings, dyes, color pastes, paints, inks, food, cosmetics, pharmaceuticals, pesticides, papermaking, magnetic particles, ferrites, photosensitive films, new energy lithium batteries, nano materials, etc. The horizontal sand mill integrates the essence of the current domestic and foreign models. Compared with ball mills, roller mills, colloid mills and other grinding equipment, sand mills have the advantages of high efficiency, strong work continuity, less pollution, reliable automatic control, as well as low cost, compact structure, generous shape, easy use and maintenance, etc.

According to the different structures, the horizontal sand mill can be divided into ordinary horizontal sand mill, wheel pin horizontal sand mill, tooth-gear horizontal sand mill and turbine horizontal sand mill.

Characteristics of the Horizontal Sand Mill

1. When in operation, the raw materials are pressed and sent into the grinding tank from the bottom to the top by the feeding pump, and discharged from above. All the raw materials sent into the grinding tank are 100% completely ground, so the complete grinding effect can be achieved. In addition, the whole grinding process is carried out in a fully enclosed grinding tank, so there is no problem of solvent volatilization polluting the air, which can ensure the physical and mental health of the staff.

2. The horizontal sand mill is composed of a fuselage, a main drive, a disperser, a feeding pump, a stepless speed transmission, a cooling system, an electrical controller, etc. In terms of structure, the overall and integral design is adopted, integrating the fuselage, the feeding pump and the electrical control box, so that the horizontal sand mill occupies less space and is easy to operate. The grinding tank is designed with a cooling jacket type, so that the cooling water can be in and out to cool down the high temperature generated during the grinding process.

3. The horizontal sand mill feeding pump adopts an internal tooth arc pump, which is suitable for various viscosities. The pump motor adopts stepless speed regulation to control the flow rate, with high production efficiency and good dispersion function. (The feeding pump can also be customized according to the user's requirements)

4. This series of horizontal sand mill adopts a fully flameproof design, which is suitable for production in flammable and explosive environments, safely and efficiently.

5. There are two kinds of sand mill materials, the stainless steel and carbon steel. The grinding disc materials are stainless steel, manganese steel and alloy steel (if there are special requirements, it can be customized. Please indicate when ordering)

6. The horizontal sand mill is easy to clean and change color, easy to operate, stable in operation, and suitable for continuous grinding operations.

7. High wear-resistance of inner cavity, multiple varieties of selection, strong applicability.

8. It is suitable for high-volume and continuous production.

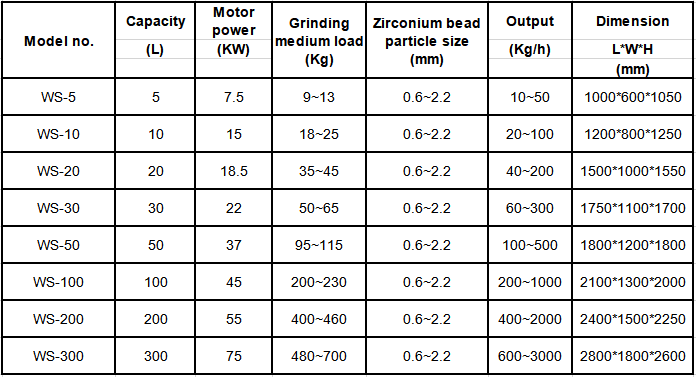

Technical Parameter and Specifications

Note:

1. There are several elements that need to be paid attention to in the selection of micron-level horizontal sand mills:

a. Characteristics of material properties

b. Yield

c. The viscosity and solid content of the material

d. Grinding fineness requirements

2. The micron-level horizontal sand mill can be divided into disc front-end discharge and disc back-end discharge from the structure.

3. The horizontal sand mill can be divided into explosion-proof and non-explosion-proof type.

4. The horizontal sand mill needs to determine the internal material of the grinding chamber according to the material nature.

Our engineering team can walk you through the design process and help you choose the suitable horizontal sand mill that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms