Dusting Bags

Dusting Bags

Overview

The dusting bag, also called filter bag, is the key element that determines the dust removal efficiency and working temperature of the bag type dust collector, and the cost of replacing the filter bags is the main maintenance cost of the bag type dust collector. Therefore, the working life of the dusting bag is related to the operating status and cost of the dust collector, so it is particularly important to choose the appropriate filter material and a reasonably designed structure.

The selection of filter materials should be based on the temperature, humidity and chemical characteristics of the flue gas, the size, weight, shape, abrasiveness of the particles, and the dust concentration, filtration speed, dust cleaning method, emission concentration and the working system of the dust collector and other factors. Under normal circumstances, needle felt dusting bag is used for pulsed air blowing bag type dust collectors, and woven fabric dusting bag is used for chamber reverse blowing dust collector or mechanical vibrating dust collector.

Our company specializes in the production of 208 needle felt dusting bag, 729 needle felt dusting bag, polyester needle felt dusting bag, water-proof, oil-proof and anti-static needle felt dusting bag, acrylic needle felt dusting bag, glass fiber needle felt dusting bag, FMS high temperature needle felt dusting bag, Metas needle felt dusting bag, Nomex high temperature needle felt dusting bag, Huate high temperature needle felt dusting bag, PPS, P84 high temperature needle felt dusting bags etc.. We have special filter clothes, such as aramid, PTFE, PVDF, etc., for high temperature applications.

Features and Advantages

For the filter cloth, it is not only the wear and tear of the material itself that affects its service life, but more importantly, the corrosion of the filter cloth by the working substance, therefore, the requirements for the industrial filter cloth are very high.

Our filter bag cloth has the following features and advantages:

● The capture effect after the solid is good and the service life is long;

● The filtration speed is fast, the blockage is less, and the filtration speed is stable;

● The filter residue has good peelability, no expansion and contraction, and good dimensional stability.

● Approach to zero emission, can meet the most stringent environmental standards;

● Good ash cleaning, can provide higher ventilation, or can reduce the pressure difference;

● The extension of the life of the filter bag and the reduction of the number of cleaning times reduce the maintenance cost of the equipment;

● Higher air-to-cloth ratio, smaller dust collector can be designed, and energy consumption is reduced when the differential pressure is reduced;

Application

Flue gas treatment and dust removal systems for ironworks, steelworks, ferroalloy plants, refractory plants, foundries, power plants, etc. Flue gas filtration for garbage incinerators, coal-fired boilers, fluidized bed boilers, etc. Asphalt concrete mixing, building materials, cement ceramics, lime, gypsum and other production sites. Aluminum electrolysis, lead, tin, zinc, copper and other rare metals smelting flue gas filtration, fine material recovery, liquid and solid separation. Liquid-solid separation and fine material recovery in chemical, coke, carbon black, dyes, pharmaceutical, plastic and other fields. Dust control and purification collection in mining, grain processing, flour, electronics industry, wood processing, etc.

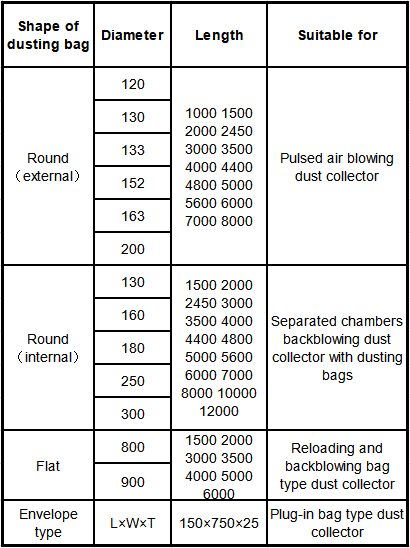

Recommended Size of Dusting Bag

Unit:mm

Performance Parameter of Dusting Bags

(Choose different dusting bags and cages for different processes)

PTFE dusting bag | PPS dusting bag | Aramid dusting bag |

|

|

|

Grammage:700g/m² Thickness:1.0mm Working temp.:≤260℃ Instant temp.:1300℃ Chemical properties:Resistant to acids and alkalis, not flammable | Grammage:500g/m² Thickness:1.6mm Working temp.:≤160℃ Instant temp.:190℃ Chemical properties:good resistance to acid and alkali | Grammage:500g/m² Thickness:2.2mm Working temp.:≤204℃ Instant temp.:240℃ Chemical properties:Anti-abrasion, anti-acid and alkali, anti-oxidation |

P84 dusting bag | PE dusting bag | Glass fiber dusting bag |

|

|

|

Grammage:500g/m² Thickness:1.7mm Working temp.:≤130℃ Instant temp.:150℃ Chemical properties:good performance in anti-acid and alkali | Grammage:500g/m² Thickness:1.8mm Working temp.:≤130℃ Instant temp.:150℃ Chemical properties:Resistant to abrasion, oxidation, acid and alkaline corrosion | Grammage:500g/m² Thickness:1.8mm Working temp.:≤260℃ Instant temp.:300℃ Chemical properties:Acid-resistant, alkali-resistant and hydrolysis-resistant |

Our engineering team can walk you through the design process and help you choose the suitable dusting bags that best fit your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms