LPM Air-box Series Pulse Jet Baghouse Dust Collector

LPM Air-box Series Pulse Jet Baghouse Dust Collector

Overview

LPM air-box series pulse Jet baghouse dust collector, also known as air-box series pulsed dust collector, is a high-efficiency dust collector developed by our company. Our company draws on the advanced dust removal technology at home and abroad, adopts high-pressure air blowing, positive pressure release, and integrates the advantages of varieties of dust collectors such as individual chamber reverse blowing type and pulse jet air blowing type, which solves the shortcoming of insufficient kinetic energy intensity when air blowing for each chamber, and overcomes the disadvantage that the dust cleaning must happen at the same time as pulse jet air blowing filtration. Due to the use of high-energy dust cleaning technology and off-line dust cleaning in the chamber structure, it has the characteristics of high dust cleaning efficiency, fast speed and short cycle time, which expands the adaptability of this type of dust collector, prolongs the service life of the filter bags, and improves the dust removal efficiency, which can reach more than 99.9%. It can handle not only general concentrations of dusty gases, but also high concentrations (up to 1000g/m3) of dusty gases. LPM air-box series pulse jet dust collector has been widely used in electric power, chemical industry, metallurgy, steel, cement and other industries.

Structure and Working Principle

The main structure of LPM air-box series pulse jet dust collector is composed of several parts, such as the box, the bag chamber, the dust hopper, the air inlet and outlet, etc., and is equipped with foundation pillars, ladders, railings, access doors, air circuit system of compressed air, dust cleaning control system, dust discharge system, etc. The air-box series pulse jet dust collector mainly adopts the structure of separated chambers and inlets the air from the lower side. The dust collector is divided into several boxes, with 32, 64, 96 and 128 filter bags for each. And there is a cylinder-driven poppet valve on the side outlet pipe of each box. The dusty flue gas enters the dust hopper from the middle box through the intake airway, and some larger dust particles fall directly into the dust hopper due to inertial collision and natural sedimentation; Other dust particles are carried up by the air flow into the bag chambers. After being filtered by the filter bags, the dust particles are trapped on the outside of the filter bags, and the purified gas enters the upper box from the inside of the filter bag, and then discharges into the atmosphere through the poppet valve and air outlet. The dust in the hopper is discharged regularly or continuously by the rigid impeller discharger and the screw conveyor. As the filtration process goes on, the amount of dust attached to the outside of the filter bags increases, resulting in a gradual increase in the resistance of the dust collector itself. When the resistance reaches a preset value, the cleaning controller sends a signal, first closing the poppet valve of one bag chamber to cut off the air flow to the chamber, and then opening the electromagnetic pulse valve, spraying the compressed air of 0.4-0.6MPa into the bag chamber for a very short time of 0.1-0. 2 seconds. The compressed air expands at high speed in the bag chamber, making the filter bags vibrate at high-frequency, coupled with the effect of reverse air flow, so that the dust cakes attached to the outside of the filter bags begin to deform and fall off. After fully considering the sedimentation time of the dust (to ensure that the dust can effectively fall into the dust hopper), the poppet valve is opened, and this bag chamber enters the filtration state again, and the next bag chamber begins to enter the dust cleaning state. Thus, one cycle is completed. The LPM air-box series pulsed dust collector consists of multiple independent bag chambers, and each bag chamber is carried out separately in a certain order during dust cleaning, without interfering with each other, so as to achieve the long-term continuous running of the equipment. The above-mentioned dust cleaning process is automatically controlled by the dust cleaning controller, which is divided into two types, the timing type and the constant resistance type, and can be selected according to customers requirements.

Main Performance Characteristics

a). High reliability design to ensure the long-term and stable operation of the dust collector with the main production line, and the maintenance work is very little.

b). High adaptability design, the PLM dust controller can adapt to a wide range of differences in the properties of dusty gases.

c). Special structural design and strict selection of filter materials and ancillary parts can meet the extremely strict environmental protection requirements.

d). The emission can be ensured to be less than 50mg/Nm3.

e). Optimized inlet and outlet airway design, which is conducive to uniform airflow distribution.

f). Anti-leakage design to ensure that the dust collector eliminates air leakage.

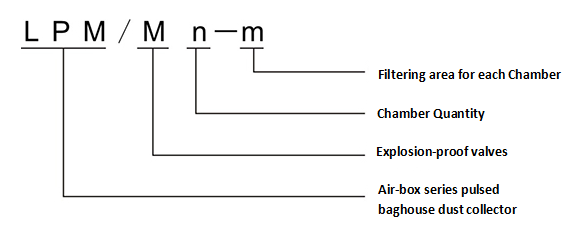

Part Number Illustration

Ordering Instruction

(1) The main technical parameters for dust collector selection are air volume, gas temperature, dust concentration and humidity. When selecting the dust collectors, the designed values of air volume, gas temperature and dust concentration should be slightly less than the values in the technical performance table. And the filter material is subject to the inlet concentration, gas temperature and moisture content.

(2) The treated air volume and filtering air speed listed in the table are only applicable to dust concentrations greater than 100g/Nm3, however, when the dust concentration is less than 100g/Nm3, the treated air volume and filtering air speed can be increased by 20%.

(3) In the compressed air consumption column, the proposed air consumption is the large air consumption of this type of equipment, and when the inlet concentration of the dusty gas is greater than 500g/Nm3, the air consumption in parentheses shall be used.

(4) When ordering, it is necessary to know the particle size of the dust, the acid-base composition of the dust, the oxidation composition, the explosion-proof level of the dust collector equipment and the other important on-site factors.

(5) If the negative pressure of the system exceeds 6000Pa, it needs to be pointed out in advance in order to enhance the strength and stiffness of the shell during design and production period.

(6) The discharge system of the dust hopper can be set up according to the process requirements.

Technical Parameter Table of LPM Air-box Series Pulse Jet Dust Collector

| Parameter | Air Volume | Filtering Speed(m/min) | Filtering Area | Qty. Of Filter bags(pcs) | Resistance(Pa) | Dust Concentration(g/m³) | Insulation Area(m²) | Weight |

| Part No. | (m³/h) | (m²) | (kg) | |||||

| Mar-32 | 6900 | 1.2-2.0 | 93 | 96 | 1470-1770 | <1000 | 26.5 | 2880 |

| Apr-32 | 8930 | 124 | 128 | 34 | 4080 | |||

| May-32 | 11160 | 155 | 160 | 41 | 5280 | |||

| Jun-32 | 13390 | 186 | 792 | 48.5 | 6480 | |||

| Apr-64 | 17800 | 248 | 256 | 70 | 7280 | |||

| May-64 | 22300 | 310 | 320 | 94 | 9960 | |||

| Jun-64 | 26700 | 372 | 384 | 118 | 11640 | |||

| Jul-64 | 31200 | 424 | 448 | 142 | 13320 | |||

| Aug-64 | 36700 | 496 | 512 | 166 | 15000 | |||

| Apr-96 | 26800 | 1.2-2.0 | 372 | 384 | 1470-1770 | <1300 | 110 | 10452 |

| May-96 | 33400 | 465 | 480 | 120 | 12120 | |||

| Jun-96 | 40100 | 557 | 576 | 130 | 14880 | |||

| Jul-96 | 46800 | 650 | 672 | 140 | 16920 | |||

| Aug-96 | 53510 | 744 | 768 | 150 | 19810 | |||

| Sep-96 | 60100 | 836 | 864 | 160 | 21240 | |||

| 96-2×5 | 66900 | 929 | 960 | 175 | 25200 | |||

| 96-2×6 | 80700 | 1121 | 1152 | 210 | 30240 | |||

| 96-2×7 | 94100 | 1308 | 1344 | 245 | 35280 | |||

| 96-2×8 | 107600 | 1494 | 1536 | 280 | 40320 | |||

| 96-2×9 | 121000 | 1681 | 1728 | 315 | 45360 | |||

| 96-2×10 | 134500 | 1869 | 1920 | 350 | 50400 | |||

| 128-6 | 67300 | 1.2-2.0 | 935 | 768 | 1470-1770 | <1300 | 125 | 24120 |

| 128-9 | 100900 | 1402 | 1152 | 196 | 31680 | |||

| 128-10 | 112100 | 1558 | 1280 | 205 | 34680 | |||

| 128-2×6 | 134500 | 1869 | 1536 | 323 | 43920 | |||

| 128-2×7 | 156985 | 2181 | 1792 | 247 | 52680 | |||

| 128-2×8 | 179450 | 2492 | 2048 | 262 | 60000 | |||

| 128-2×9 | 201900 | 2804 | 2304 | 277 | 66480 | |||

| 128-2×10 | 224300 | 3115 | 2560 | 292 | 72000 | |||

| 128-2×11 | 247600 | 3427 | 2816 | 307 | 78480 | |||

| 128-2×12 | 269100 | 3728 | 3072 | 322 | 86400 | |||

| 128-2×13 | 291600 | 4050 | 3328 | 337 | 93600 | |||

| 128-2×14 | 314000 | 4361 | 3584 | 252 | 100800 |

For detailed information about LPM air-box series pulse jet baghouse dust collector, please contact Zhongcheng Lijing for reference. Our engineering team can walk you through the design process and help you choose the suitable baghouse dust collector that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms