HEZ Horizontal Electrostatic Dust Collector

HEZ Horizontal Electrostatic Dust Collector

Overview

Horizontal electrostatic dust collector is a kind of high-efficiency and energy-saving flue gas purification equipment, which has the advantages of high dust collection efficiency, large amount of flue gas treatment, long service life and low maintenance cost. HEZ series horizontal electrostatic dust collector is a new type of product developed by our company after introducing and digesting various advanced technologies, and has been assessed by the State Environmental Protection Administration as a national key environmental protection practical technology promotion project, with the characteristics of low resistance, uniform air distribution, stable operation and high dust removal efficiency, and is widely used in the purification of industrial waste gas and the recovery of useful substances in electric power, metallurgy, chemical industry, building materials, light industry and other industries. HEZ series electrostatic dust collector uses electrostatic purification method to capture dust in exhaust gas. Its purification work mainly relies on two systems, the corona electrode and the precipitation electrode. In addition, the electrostatic dust collector also includes the vibrating and dust cleaning mechanism of the two electrodes, the gas uniform distribution device, the discharge device and the shell.

Working Principle of HEZ Series Horizontal Electrostatic Dust Collector

HEZ horizontal electrostatic dust collector is a kind of high-efficiency dry dust collector.

Its dust removal principle is as below:

when the dust-containing gas enters the electrostatic dust collector from the inlet pipe, and passes through the high-voltage electric field formed between the negative electrode (also known as the corona electrode) and the positive electrode (also known as the precipitation electrode), the gas is ionized, and many positive ions and electrons are generated. The positive ions are attracted and move to the negative electrode, and the electrons with negative electricity move to the positive electrode. The electrons are attached to the dust particles when they pass through them and move together to the positive electrode. After the dust particles reach the positive electrode, the negative charge is handed over to the positive electrode and the dust particles themselves become neutral particles attached to the positive electrode. Then the dust particles fall into the dust hopper through strong vibration of the hammer shape of side flexion arm, and finally are discharged and recovered by the dust discharge device, leaving the purified gas discharged into the atmosphere, thus realizing the purpose of separating the dust particles from the gas.

Performance Characteristics

(a). It adopts a full set of computer design, which is accurate and reliable.

(b). The shell adopts a frame structure, with high strength and good stability, and can be designed according to different pressure and temperature resistance requirements.

(c). The inlet and outlet mode can be designed into various forms according to the process layout and flue gas characteristics, and the process layout is flexible and changeable.

(d). The airflow uniform distribution device of flow blocking and diversion type is adopted, so that the airflow is well distributed, and there is no dust blockage.

(e). The precipitating electrode adopts 480C type plate, and the discharge electrode adopts a new type of RS tubular spiky wire, which has a reasonable pole fit, uniform discharge and good discharge performance.

(f). The connection between the discharge electrode and the frame is reasonable, and there is no drop or disconnection.

(g). The hammer shape of side flexion arm vibrates, the vibration force is transmitted evenly with good effect, and the dust is easy to clean.

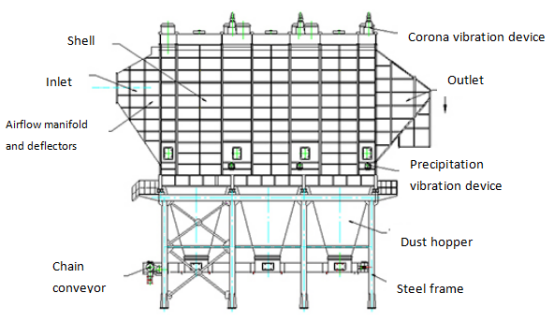

Outline Diagram of HEZ Electrostatic Dust Collector

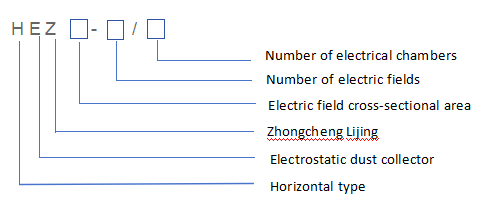

The Model Number Indication

The model number of HEZ horizontal electrostatic dust collector produced by our company is expressed as below:

For example, HEZ40-3/1 is expressed as below:

The horizontal electrostatic dust collector has an electric field cross-sectional area of 40 square meters

The number of electric fields is 3

The number of electrical chambers is 1

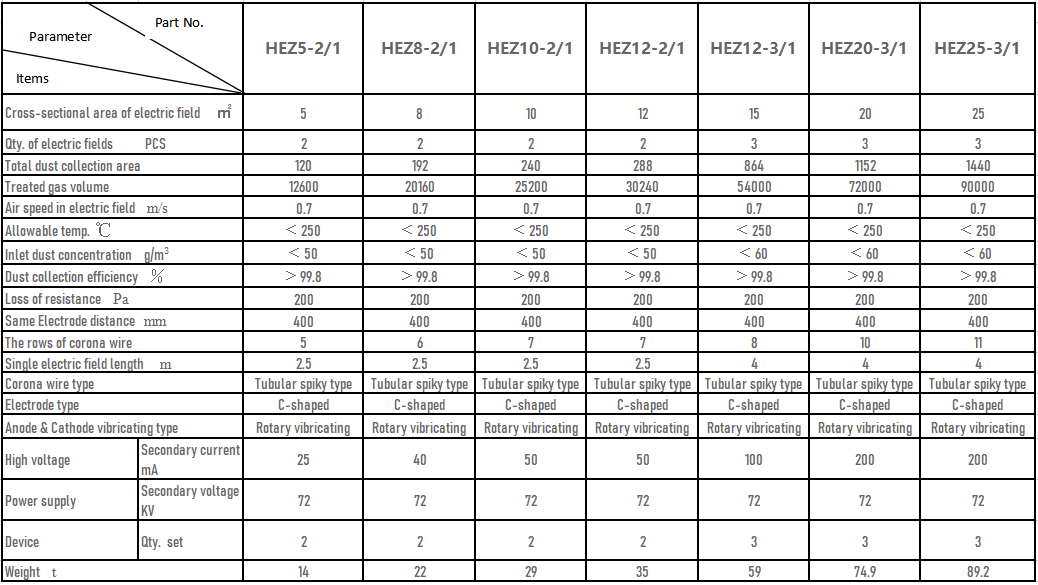

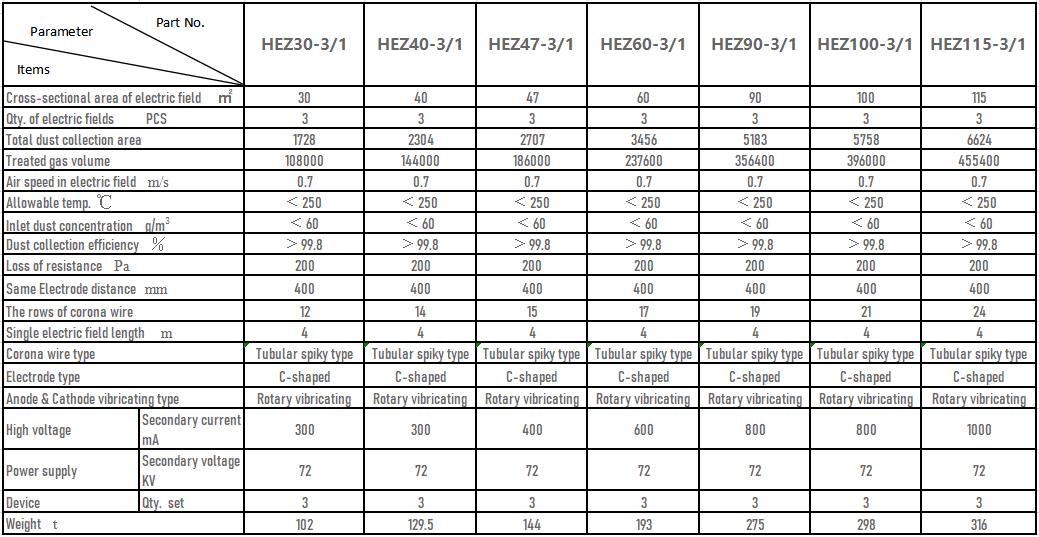

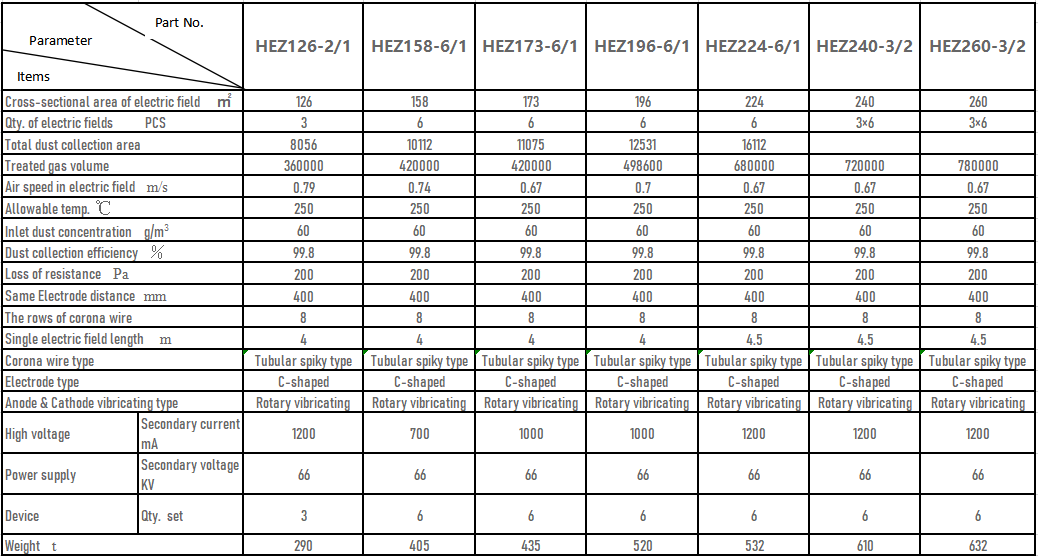

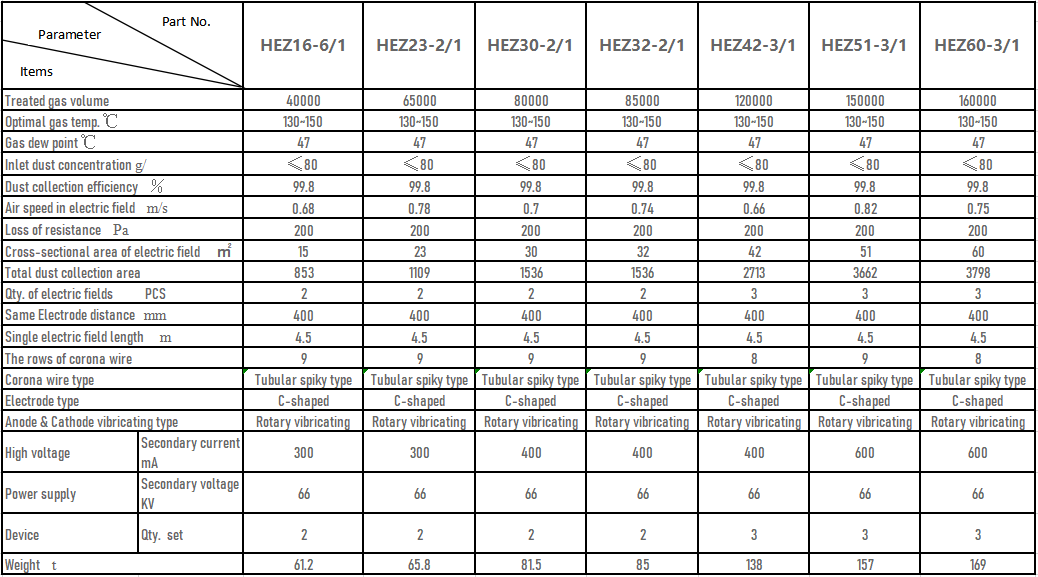

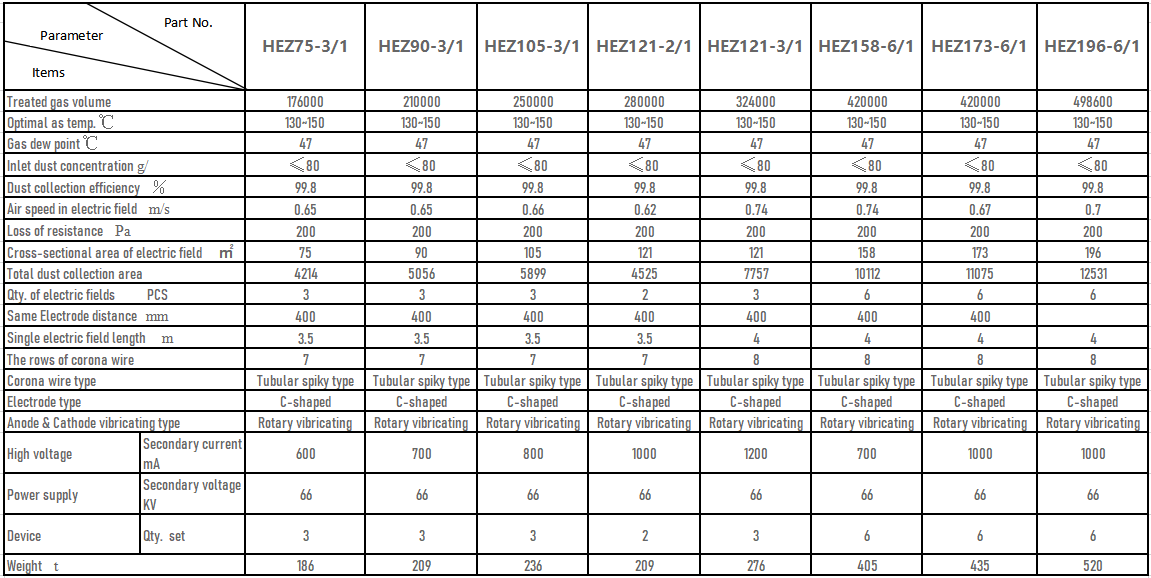

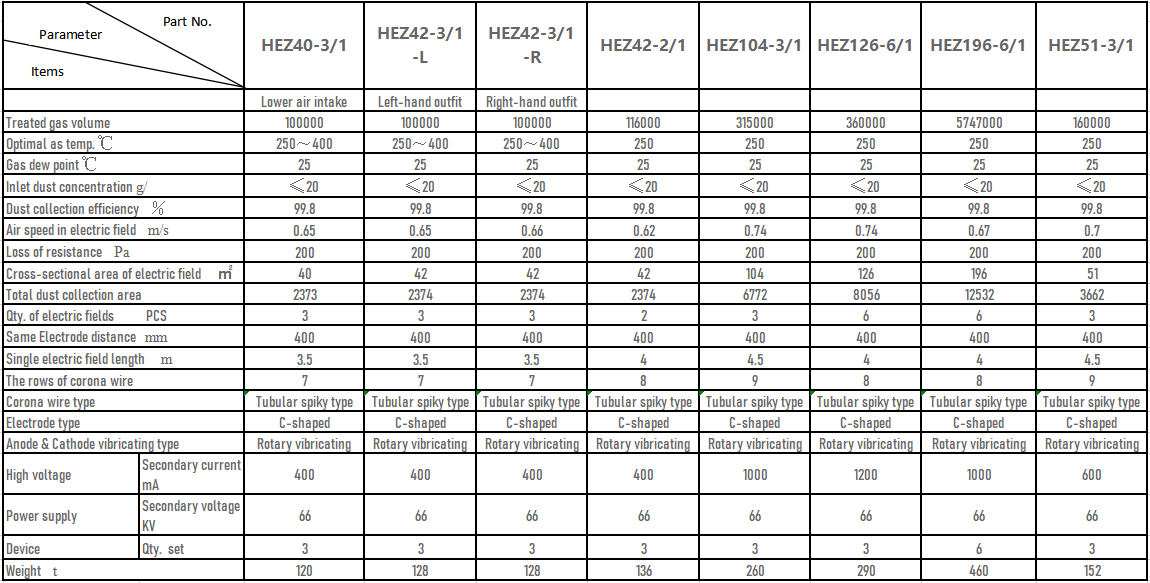

Technical Data and Specifications

Technical Performance and Specifications of HEZ type Cooling Electrostatic Dust Collector

The Composition and Basic Structure of HEZ Electrostatic Dust Collector

HEZ series electrostatic dust collector is composed of air inlet and outlet, shell, air diversion device, cathode and vibrating system, anode and vibrating system, insulation system, dust hopper and dust discharge system, electrical system and other devices.

Its basic structure is briefly described as follows:

1. Inlet and outlet

The inlet and outlet are the steel structure parts at both ends of the electrostatic dust collector housing that introduces the dusty gas and discharges the purified gas, which is designed according to the process requirements and the amount of exhaust gas to be treated.

2. Air diversion device

At the air inlet of the electrostatic dust collector, one to three airflow manifolds and diversions are set according to the working conditions to ensure that the dusty gases entering the high-voltage electric field evenly and stably, which is very important to ensure the dust removal effect.

HEZ electrostatic dust collector is generally equipped with more than two air manifolds and diversions (mostly porous plates) to ensure the wind speed of the electric field:

(1) The flow velocity at any point does not exceed ±40% of the average flow velocity of the section

(2) On any measurement section, the flow velocity of more than 85% of the measuring points shall not differ from the average flow velocity by ±25%

3, Housing

The shell of this series of electrostatic dust collectors are all made of steel, with novel design, reasonable structure and easy installation.

The shell is basically composed of frame, plate, top beam, column, bottom beam, top cover plate, side plate, end wall, access door, walkway, ladder, etc.

The bottom beam is respectively provided with a fixed bracket and a movable bracket to eliminate the thermal displacement caused by the heating of the shell (that is, it can move freely along the respective expansion direction on each fulcrum).

The shell is equipped with a flow blocking baffle and a wind deflectors to prevent the dusty air flow from bypassing the electric field and directly discharging from the inlet to the outlet and reducing the dust removal efficiency.

The top cover is composed of two layers of steel plates, the inner layer plays the role of sealing the electric field, and the outer layer plays the role of rain and lightning protection equipment. There are two kinds of top covers, the airtight cover and the explosion-proof cover. Use the airtight cover when the dust and smoke do not contain flammable or explosive gas, and use the explosion-proof valve type top cover if the treated gas contains flammable and explosive gas. When the combustion and explosion occur in the electrostatic dust collector, the top cover and the explosion-proof valve can automatically relieve the pressure, so that the electrostatic dust collector can operate safely and prevent accidents.

The outer side of the shell is laid with an insulation layer, and the insulation layer is made of insulation materials, steel wire mesh and galvanized sheet protective layer.

After the shell is fully installed, the air leakage test should be carried out before laying the insulation layer, and the air leakage rate should be no more than 5%.

4. Cathode and cathode vibrating system

The cathode (corona electrode) is required to have good discharge performance (i.e., low corona voltage and high corona current), and have certain mechanical strength and corrosion resistance. At present, there are two commonly used cathodes, the star type and the spiky wire type. The actual application shows that under the same working voltage, the corona current of spiky wire type is larger than that of the star type, which is conducive to the capture of high concentration of fine dust particles. At the same time, due to the strong flow of electrons generated by the tip of the thorn, the electric wind of the electrostatic dust collector is increased(the movement of the gas to the precipitation electrode is called electric wind), which is beneficial to reduce corona occlusion.

The HEZ electrostatic dust collector adopts the tubular spiky wires produced by our company, which has good discharge performance, high mechanical strength, accurate installation and positioning, less dust accumulation, and easy dust cleaning. The tubular spiky corona wire is fixed on the corona frame after being tensioned with special tools, and the frame is suspended on the upper conical insulated porcelain sleeve by four booms, and temperature control measures are taken to prevent the electric breakdown caused by condensation on the surface of the porcelain sleeve, so as to ensure the reliability of the cathode system.

In order to ensure the discharge of the tubular spiky wire thorns, it is very important to clean up the dust in time, and the dust cleaning should be continuous, timely and clean. HEZ type cathode vibrate powerfully by adopting the top circumferential arm rotary vibrating mechanism ,to clean dust thoroughly and reliably, which provides strong support for strengthening the reliability of the cathode system.

Our engineering team can walk you through the design process and help you choose the suitable electrostatic dust collector that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms