Dusting Bag Cages

Dusting Bag Cages

Overview

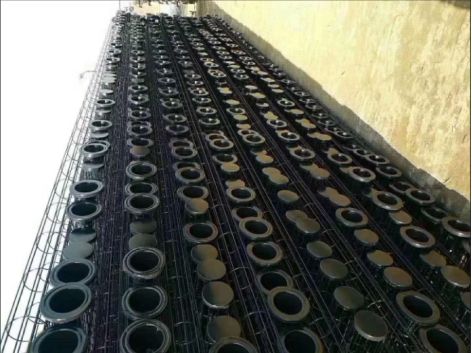

The dusting bag cage (skeleton) is one of the important components of the pulsed bag type dust collector. The dusting bag cage is a cage-shaped frame welded with several steel wire strips and support rings, and the bottom of the bag cage has a circular chassis, whose upper end is connected with the porous plate in different ways with different installed interfaces, and the role of the frame is to make the dusting bag not be sucked up. The quality of the dusting bag cage directly affects the service life of the dust collectors. When welding, the solder joint is required to be smooth and burr-free.

There are many ways to connect the dusting bag cage and the porous plate, which can be summarized as follows:

1. Shaft plug-in type. It is a connection method adopted by the MC type pulsed dust collector with dusting bags. The dusting bags and bag cages are inserted and withdrawn from the upper part of the porous plate. The frame is held in place by four platens and hold-down bolts, each pressed against two adjacent frames. When the frame is withdrawn or inserted, the bolt is loosened first and then the pressure plate can be turned 90°. There is no resistance to the frame by this connection method, and the operation is convenient.

2. Four-point bayonet type. It consists of a plug and a socket. The plug is connected with the frame, and the socket is fixed on the porous plate or made by the venturi tube.

3. Fixing type by expansion ring . It uses the short tube at the upper end of the frame as an elastic expansion ring, and fixes the frame on the annular groove at the waist of the venturi tube by the contraction force of the expansion ring. During installation, the mouth of the dusting bag is folded inward between the groove of the venturi tube and the convex part of the expansion ring, and then tightened with a clamp, which is simple in structure, but more troublesome in loading and unloading.

4. Fixing type by spring. The frame of this type is made into an annular worktops that protrudes inward at the upper mouth. The lower box of the dust collector is equipped with several rows of spring fixing frames and springs corresponding to the dusting bags, and a spring seat is installed on the bottom disc of the frame, the springs of the frame are aligned with the spring seats and pressed down during installation, and the frame is pushed to the venturi tube after the upper mouth is aligned with the venturi tube, and then the dusting bag is tied. This structure is simple and reliable in application.

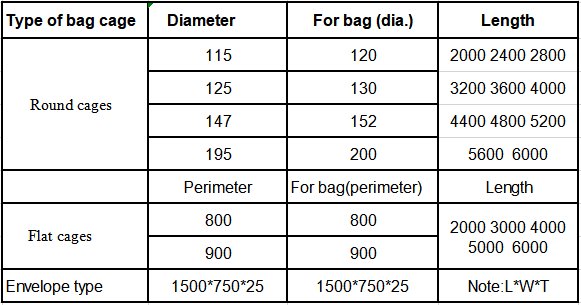

Recommended Cages for Dusting Bags

(Unit: mm)

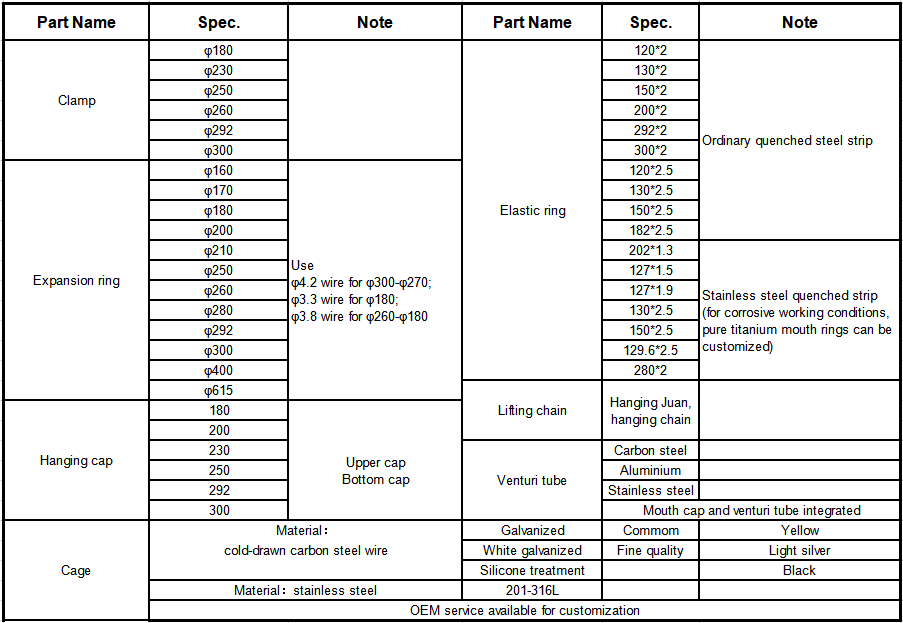

List of Main Components

Our engineering team can walk you through the design process and help you choose the suitable dusting bag cages that best fit your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms