MC-II Series Pulse Jet Baghouse Dust Collector

MC-II Series Pulse Jet Baghouse Dust Collector

Overview

MC-II series of pulse jet baghouse dust collector is a new one improved on the basis of MC-I. In order to further improve the MC-I dust collector, the original drawing was modified, and the modified MC-II dust collector retains the advantages of MC-I with high purification efficiency, large gas processing capacity, stable performance, easy operation, long filter bag life and small maintenance workload. Moreover, the reform of the structure and pulse valve solves the problems of open air placement and low compressed air pressure. It is suitable for machinery, metallurgy, rubber, flour, chemical, pharmaceutical, carbon, building materials, mining and other industries.

Characteristics

1. On the basis of retaining the advantages of the original MC-I dust collector, the MC-II dust collector adopts a low-resistance DMF-Z pulse solenoid valve, which doubles the life of the collector’s control system and filter bags, and reduces the maintenance workload.

2. The compressed air used for dust cleaning has been reduced from the original pressure of 5-7 kgf/cm2 to the current 3 kgf/cm2, but the dust cleaning effect can still keep the same as that of 5-7kgf/cm2, so as to expand the scope of application.

3. Due to the improvement of the structure, the tightness of the dust collector is enhanced, and the air leakage volume can be less than 10%, which further improves the quality of the dust collector.

4. The fixing method of the filter bag has been updated, which is convenient for future repair and maintenance.

5. A protective cover has been added onto the air blowing device , and it features rainproof function, therefore the dust collector can be placed in the open air without a rain shelter, which reduces the construction investment.

6. A star shape of discharger is installed for dust cleaning to replace the original screw conveyor, which improves the dust cleaning efficiency and reduces maintenance workload. It seals tightly, and can quickly discharge the dust .

Structural Principle

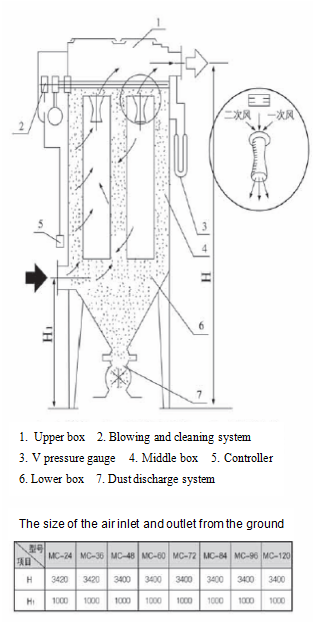

MC pulse & bag filtering type dust collector is composed of 5 parts:

The upper housing, consisting of a liftable cover and an air outlet.

2. The middle housing, composed of porous plates, filter bags and venturi tubes.

3. The lower housing, composed of air inlet, dust hopper and inspecting door.

4. Dust discharge system, composed of reducer, dust conveying and discharging device.

5. Air blowing system, composed of pulse controller, electromagnetic pulse valve, blowing pipe, air bag and protective devices.

Working Principle

The dusty gas enters the dust hopper or the filter bag house from the air inlet, filtered through the filter bags into purification gas, and enters the clean room, and then discharged by the fan through the exhaust port of the clean room. The dust accumulates on the outer surface of the filter bags, and continues to increase, so that the resistance of the dust collector continues to rise. In order to make the equipment resistance not exceed 1200Pa, and keep the collector continuing to work, the dust on the filter bags have to be cleaned regularly. Dust cleaning is conducted by starting up the pulse valve in a regular sequence by the pulse controller, so that the compressed air (0.5~0.7MPa) in the bag is sprayed out from the orifice of the air blowing pipe (called primary air), and the surrounding air (called secondary air) which is several times more than the primary air is induced through the venturi tube of the dust removal cages into the filter bag and expands sharply in an instant, and shakes off the dust with the reverse action of the air flow to achieve the purpose of dust cleaning.

Technical Data and Specification of MC-Ⅱ

Model no. | Filtering Area m² | Dust concentration g/m³ | Filtering Speed m/min | Filtering Air Volume m³/h | Resistance | Efficiency % | Dimension | Weight kg |

MC24-Ⅱ | 18 | <15 | 2~4 | 2160~4320 | 1200-1500 | 99.5 | 1090×1678×3667 | 1133 |

MC36-Ⅱ | 27 | <15 | 2~4 | 3240~6480 | 1200-1500 | 99.5 | 1490×1678×3667 | 1485 |

MC48-Ⅱ | 36 | <15 | 2~4 | 4320~8640 | 1200-1500 | 99.5 | 1890×1678×3667 | 1495 |

MC60-Ⅱ | 45 | <15 | 2~4 | 5400~10800 | 1200-1500 | 99.5 | 2290×1678×3667 | 1730 |

MC72-Ⅱ | 54 | <15 | 2~4 | 6480~12960 | 1200-1500 | 99.5 | 2690×1678×3667 | 1950 |

MC84-Ⅱ | 63 | <15 | 2~4 | 7560~15120 | 1200-1500 | 99.5 | 3090×1678×3667 | 2230 |

MC96-Ⅱ | 72 | <15 | 2~4 | 8640~17280 | 1200-1500 | 99.5 | 3650×1678×3667 | 2400 |

MC120-Ⅱ | 99 | <15 | 2~4 | 10800~21600 | 1200-1500 | 99.5 | 4450×1678×3667 | 22870 |

Application Instructions for the Dust Collector

1. Ihe dust collector is installed at the mechanical equipment where the dust is generated, and the customer shall configure the metal or plastic pipe and dust collection hood (which can also be designed by the manufacturer) according to the size of the upper air inlet of the dust collector.

2. Before the dust collector works, check whether the maintenance door and the flange connection are strictly sealed so as to avoid air leakage reducing the dust removal efficiency.

3. The voltage of dust collector is 380V. After connecting to the external power supply, the dust collector can start to work, and when running for the first time, pay attention to the direction of rotation of the fan (if it is reversed, then, need to change the way of wiring the power supply)

4. The cover of control cabinet for the dust collector shall not be opened casually in the working room, if it is necessary to adjust the cleaning time, or overhaul the circuit, it should be stopped or cut off the power supply before proceeding.

5. Adjust the pulse interval and pulse time according to the nature of the dust and the actual dust concentration, and carry out regular dust cleaning.

6. The dust collection hood is the key accessory to ensure the dust collector unit in a good state, and the customer should make an ideal dust collection cover according to the nature of the dust and the size of the processed parts, in accordance with the principles of passing, nearing, smoothing, sealing and easy designing of the dust collection hood.

Maintenance:

1. The condition of the dust collector should be checked regularly, and the filter bag should be replaced in time if the bag is broken.

2. Generally, the dust cleaning mechanism should be inspected every 6 months.

3. We have stocked lots of ancillary parts especially for those prone to wear and tear. Customer can contact us for the ancillary parts support for maintenance purpose.

Precautions:

1. The pulse jet baghouse dust collector is not suitable for corrosive gases, and should not treat exhaust gases higher than 120 degrees for a long time. If necessary to deal with high-temperature exhaust gas, please contact us for the high-temperature filter bags.

2. If there is any abnormal phenomenon in the process of opening, stopping and running, the dust collector should stop working immediately and carry out inspection and repairs.

3. When stopping the collector, press the stop button to let the shaking mechanism run for dozens of seconds, and do not cut off the power supply directly.

Our engineering team can walk you through the design process and help you choose the suitable baghouse dust collector that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms