IN Series Modular Pulse Jet Baghouse Dust Collector

IN Series Modular Pulse Jet Baghouse Dust Collector

Features

1. Modular design and easy assembly

The whole dust collector is designed by means of assembled components, which are divided into five parts, the shell, the filtration, the pneumatic air blowing, the dust discharge and the controlling instruments. The shell is composed of different shell plates, which are fixed together by bolts and nuts without any need for welding. The filtration is composed of metal cages and filtering bags fixed by expansion rings. It is very easy to install. The pneumatic air blowing section consists of an air bag, a flooded diaphragm valve, a blow pipe and a sealing assembly, which can be easily assembled on site without any welding. The dust removal part is designed in module and can be provided in different ways according to the customer's requirements, and the assembly is fixed by bolts and nuts, without any welding. The controlling part is composed of pulse controller and differential pressure controller, etc., which can be controlled on site or by remote, according to customer needs.

2. A variety of filter materials can be adapted to varieties of industries and processes

Filter bags are the most important part for dust collectors. Zhongcheng Lijing conducts an extremely strict control on producing filter bags. We have lots of filter materials to meet with customer’s needs, such as polyurethane, polypropylene, aromatic polyamide, polyphenylene sulfide(PPS), polytetrafluoroethylene(FTFE), homopoly acrylonitrile, polyimide, glass fiber and other filter materials; And we can provide a variety of filter materials with special requirements such as grinding, coking, anti-sticking, anti-wear, anti-oil, antibacterial, anti-water, anti-acid, anti-alkali, anti-fire, anti-washing, anti-static and laminating, etc.

3. No leakage, realizing zero emissions

In the design and production process of the ordinary dust collectors, little attention is paid to the sealing of the dust collector shell, nor the fit gap between the filter bag and the dust collector. The temperature change of the dust collector and the corrosion problem of acid and alkaline are also rarely taken into consideration, so when the dust collector is run for a period of time, most of them have leakage problem. In order to achieve "zero emission", the key issue is that the dust must be designed from the characteristics of dust and its manufacturing process, and the right filter material must be carefully selected to truly achieve no leakage and "zero" emission.

4. User-friendly design and simple maintenance

For dust collectors, the most annoying thing is as below:

◆ Operation: The air blowing time and interval adjustment of the controller are complicated

◆ Maintenance: It is difficult to repair the valve and replace the filter bag

These two main problems have been considered and solved in the design process of the dust collector by Zhongcheng Lijing. It has been proved that we can replace all the 40 filter bags of a dust collector just within one hour.

5. Intelligent control

The power source of the dust collector comes from the compressed air. The function of the diaphragm valve is to make the compressed air rush into the filter bag in a very short time and close in a shorter time, so that the compressed air generates a shock wave, shaking the filter bags and peeling off the dust attached to them.

The intelligent control and high-quality diaphragm valve can greatly reduce the consumption of compressed air and save energy. Therefore, the key to the quality of the valve lies in the coordination of the action time and the closing time. According to some experiments, the difference in compressed air consumption of diaphragm valves produced by different manufacturers can be as much as 20%, not to mention that some valves cannot even be closed. The IN series dust collector adopts the diaphragm valve and controller of the Italian MECAIR brand, which are stable, durable and cost-effective.

6. Diversification of control methods

◆ manual: adjust the air blowing time and the interval time manually

◆ automatic: automatic control according to the set blowing time and interval

◆ differential pressure: according to the set differential pressure value, the dust collector will be automatically started for pulse dust removal

◆ intelligence: automatically adjust the air blowing time according to the operation of the dust collector.

The common controller only provides the adjustment of the air blowing time and interval time, and it is fundamentally impossible to automatically adjust the air blowing time and interval time according to the concentration of dust, which will cause a large amount of compressed air to be consumed meaninglessly for a long time.

7. Short lead time

Standardized design and flexible combination of product modular enable us to provide the products required by customers in a very short time.

Zhongcheng Lijing advocates "understanding the process, understanding the dust, and understanding the needs of customers", and our purpose is to provide whole systems that satisfy the needs of customers rather than only simple dust collector .

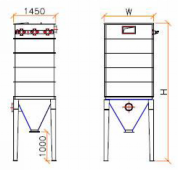

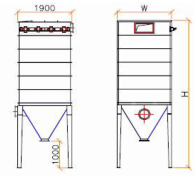

Structural Charts of 1N2, 1N3 and 1N4

|

|

|

1N2 Series | 1N3 Series | 1N4 Series |

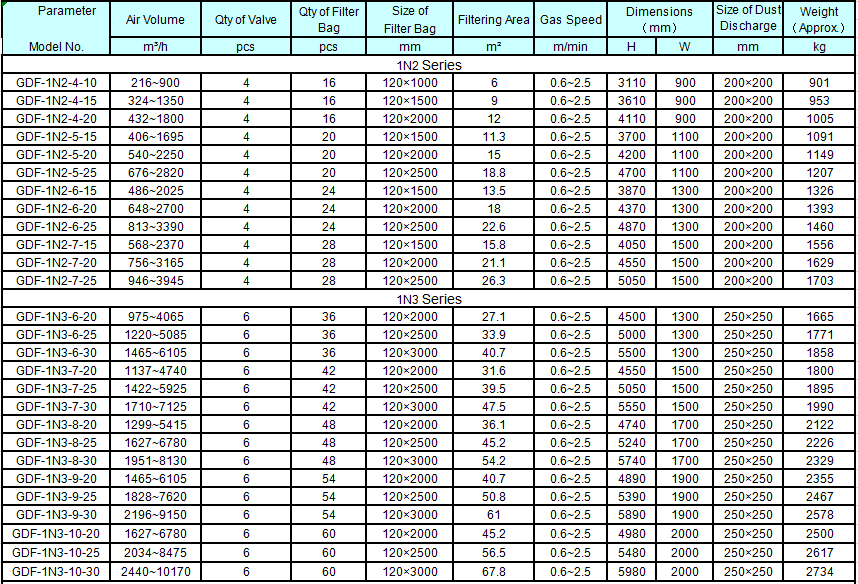

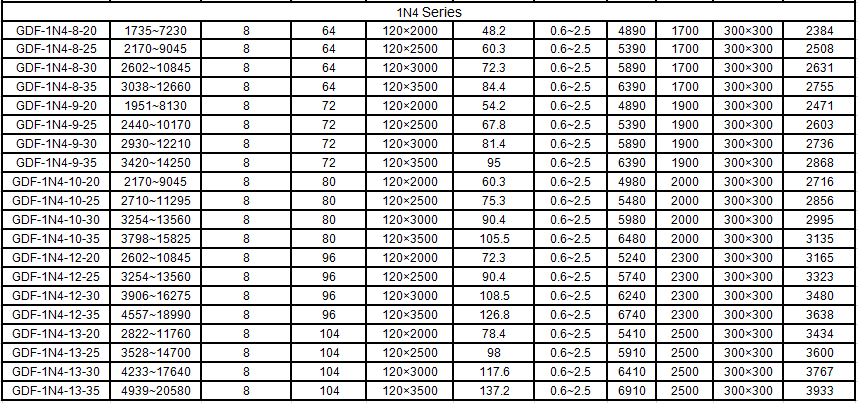

Technical Data and Specifications of 1N2, 1N3 and 1N4

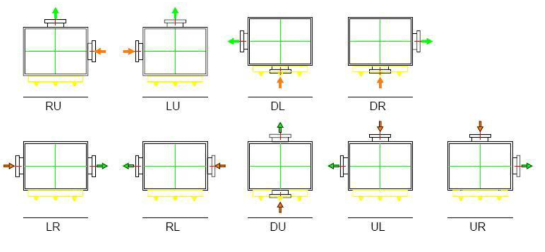

The Inlet and Outlet Patterns and Codes of 1N2, 1N3 and 1N4

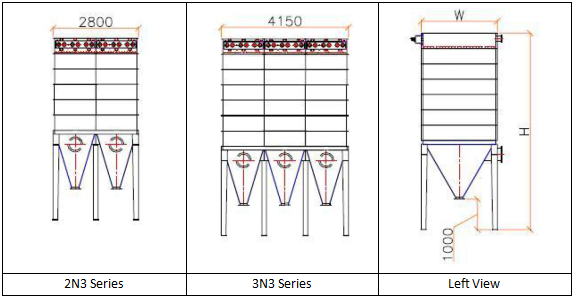

Structural Charts of 2N3 and 3N3

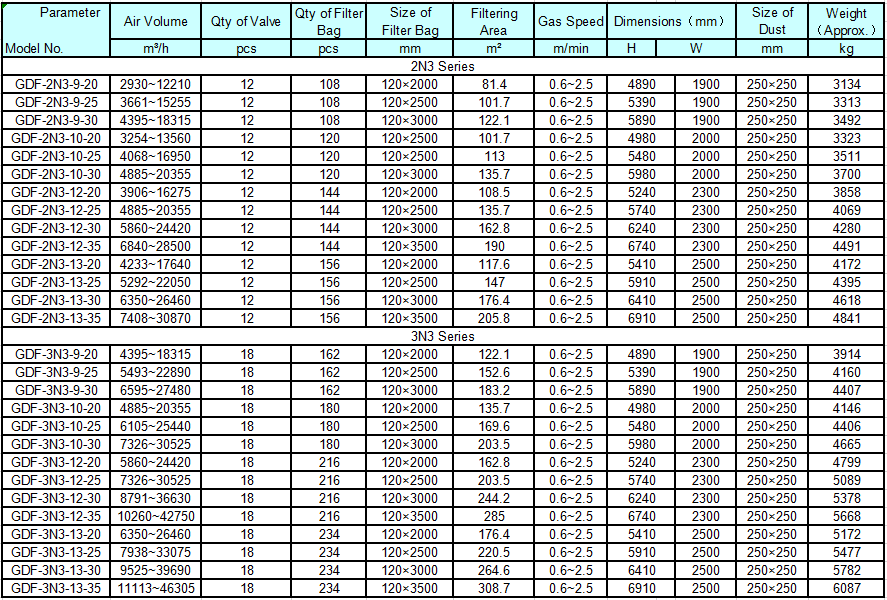

Technical Data and Specifications of 2N3 and 3N3

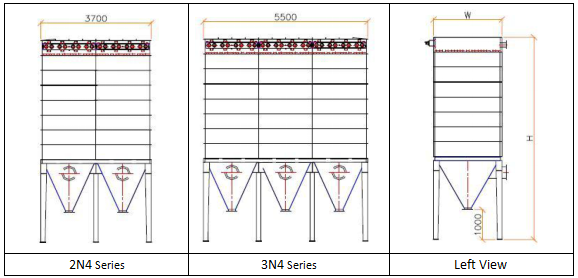

Structural Charts of 2N4 and 3N4

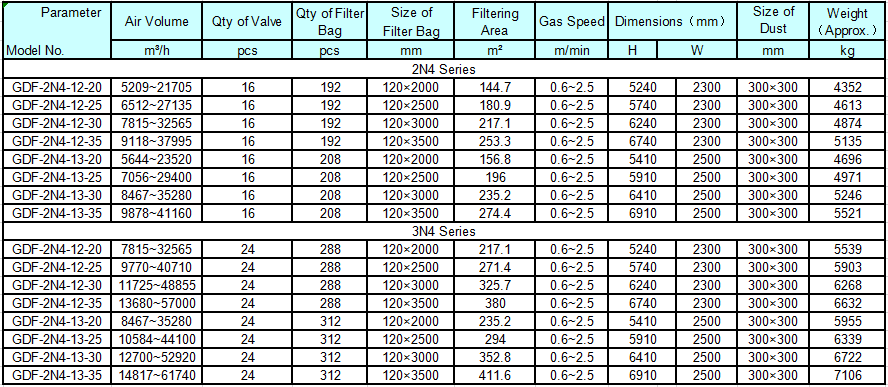

Technical Data and Specifications of 2N4 and 3N4

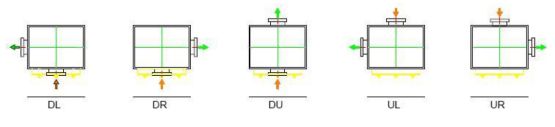

The Inlet and Outlet Patterns and Codes of 2N2, 3N3, 2N4 and 3N4

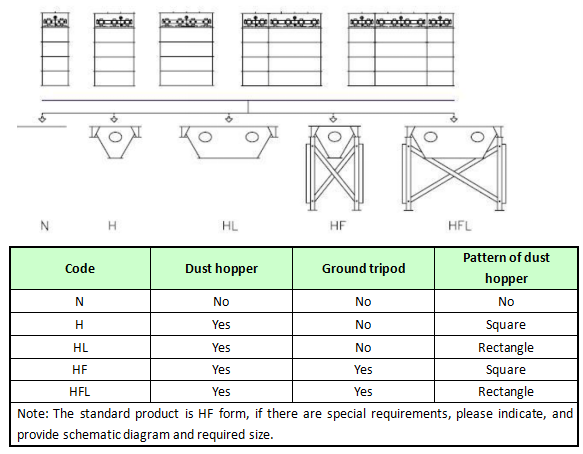

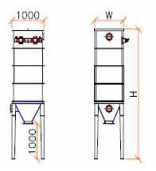

Patterns and Codes of Dust Hopper

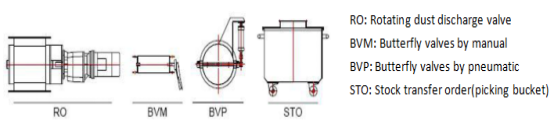

The Pattern and Code of Dust Discharging and Picking

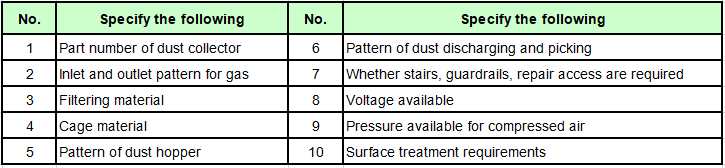

Ordering Instruction

Our engineering team can walk you through the design process and help you choose the suitable baghouse dust collector that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms