Microfilter

Microfilter

Overview

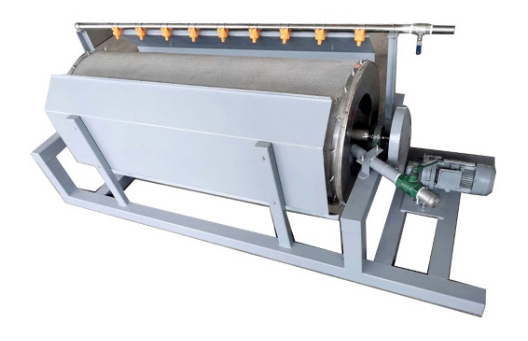

The microfilter is also called a drum-rotating mechanical grid. Because the raw water contains solid and suspended solids such as minced meat and hair, if it is not effectively removed, it is easy to cause the blockage of the equipment, which greatly affects the normal operation of the follow-up facilities, and it is difficult to remove it by conventional solid-liquid separation equipment. We have researched and produced this microfilter by mechanical filtration, which is suitable for separating the tiny suspended matter in the liquid, mainly phytoplankton, zooplankton and organic residues, to achieve the purpose of liquid purification or recovery of useful suspended solids. The fundamental difference between this microfilter and other filtration methods is that the total pore size of the filter media used - stainless steel wire mesh or microfilter screen is particularly small and very thin, this filter has high flow rate characteristics under relatively low hydraulic resistance, so that the size of the suspended solids trapped is always smaller than the micropores on these filter screens, and the microfilter is a water treatment equipment made of this principle. Microfilter is a new type of water treatment equipment, which can be used for raw water filtration (such as algae removal) in water plants, power plants, chemical plants, textile printing and dyeing factories, paper mills and other industrial water filtration and circulating cooling water filtration, wastewater purification, and sewage treatment. A typical example of the recovery of useful suspended solids in liquids with a microfilter is the pulp (fiber) recovery of papermaking white liquor, which can be as high as 98%, and the white liquor can be recycled and purified after purification, which also meets environmental emission standards.

Working Principle of Microfilter

The microfilter equipment is composed of shell, maintenance cover, filtration system, drive system, backwashing system and automatic control system.

When the water containing suspended solids particles enters the drum, the suspended solids are intercepted by the stainless steel strainer, and the water that does not contain suspended solids enters the clear water tank after filtration. When the suspended solids in the drum accumulate to a specific amount, it will cause the water permeability of the filter screen to decrease, resulting in the water level in the drum rising, when the water level rises to the set high water level, press the operation key of the automatic control system of liquid level, at this time, the backwashing water pump and the drum motor are automatically turned on at the same time, and the high-pressure water pumped out by the backwashing water pump passes through the backwashing system of the microfilter to carry out high-pressure backwashing on the rotating drum filter screen, and the suspended solids trapped on the filter screen enter the collection tank and are discharged through the sewage pipe under the flushing of high-pressure water. When the filter screen is cleaned, the water permeability of the drum filter screen rises, the water level in the drum drops, when the water level drops to the set low water level, the automatic control system works, the backwash water pump and the drum motor will automatically stop working, and the microfilter enters a new round of work cycle.

Advantages

● It occupies a small area, has a large production capacity, is convenient to operate and manage, and does not need to add chemicals.

● Continuous operation, automatic flushing, no need for special supervision, the concentration of recovered fibers can reach more than 12%.

● Simple structure, stable operation, easy maintenance and long service life.

● It has obvious effects in reducing pollution indicators of SS, COD and BOD.

● The filter screen is easy to replace, and the filter screen of different specifications can be applied to different quality requirements of water treatment.

● The equipment can remove organic and inorganic debris and various types of phytoplankton, algae or fibrous pulp from water; When used for reservoir water treatment, the algae removal efficiency is 40-70%, and the plankton removal efficiency is 97-100%.

Scope of application

● It is suitable for solid-liquid separation in the early stage of sewage treatment system and factory circulating water treatment system.

● It is suitable for wastewater treatment of industry and major farms.

● It is widely used in various occasions that require solid-liquid separation.

● Special microfiltration equipment for factory farming.

Our engineering team can walk you through the design process and help you choose the suitable microfilter that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms