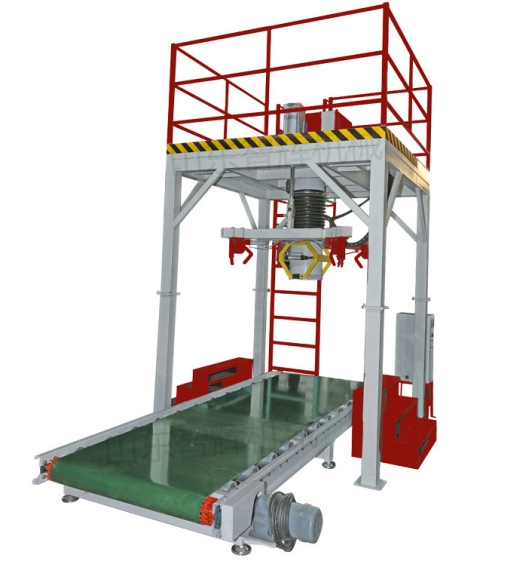

Ton Bag Packing Machine

Ton Bag Packing Machine

Overview

The ton bag packing machine is a large-scale weighing and packing equipment for ton bag packaging materials, which is a multi-purpose packaging machine integrating electronic weighing, automatic bag removal and dust removal. It has a high degree of automation, high packaging precision, adjustable packaging speed, superior structure, and a unique hydraulic lifting system which is particularly easy to handle ton bag packaging, and is very convenient for the processing of subsequent work. The ton bag packing machine is suitable for ton bag packaging of materials in mineral, chemical, building materials, grain and feed industries.

The packing machine can complete the work of bag clamping, measuring, bag pushing, etc., and is an integrated automatic packing system composed of feeding, weighing, bag clamping, dust removal, electronic control, etc. It is equipped with our heat sealing machine and sewing machine, etc. It can form a complete set of semi-automatic large bag production line. It is suitable for packaging powdery and granular materials with low viscosity or strong fluidity.

Features

1. Designed in accordance with the national GMP standard, the whole machine is made of stainless steel, and there is no dead angle in the material flow channel.

2. Complete and efficient dust collection technology to effectively protect environmental pollution and the cleanliness of the whole machine.

3. There are screw feeding, valve feeding, vibrating feeding, belt feeding, and a variety of equipment accessories are available.

4. By changing the feeding method, it can adapt to the filling and measurement of ultra-fine powder to large particle materials.

5. The packaging scale control system composed of weighing equipment of TOLEDO, Siemens and other brands.

6. It has the functions of automatic calibration, overshoot suppression, out-of-tolerance alarm, etc.

Technical Parameter

1. Measurement method: box weighing or ton measurement

2. Bag Type: Open Bag

3. Packing weight: 50-1000KG

4. Packing accuracy: ≤0.5% (varies depending on the characteristics of the material)

5. Packing speed: 1-10 bags/min

6. Applicable power supply: 3P 380V 50-60Hz

7. Machine power: 4.5kw

8. Weight: 300kg-1800kg

9. Machine volume: ≥1700*1700*3650mm

Scope of Application

It is suitable for filling non-viscous bulk powder and granular materials, such as flour, milk powder, feed, medicine, powder granular additives, rice, beans, metal powder, plastic particles and various chemical raw materials.

Our engineering team can walk you through the design process and help you choose the suitable packing machine that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms