Dismantling Line for Battery Module

Dismantling Line for Battery Module

Overview

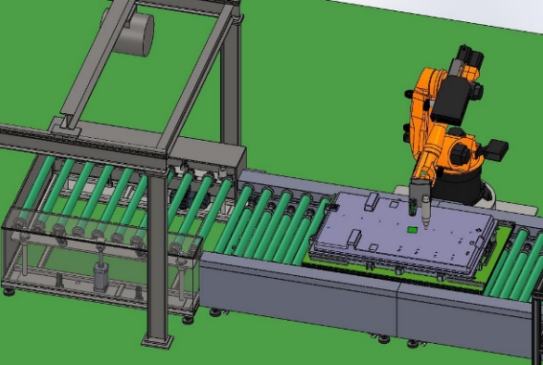

Automated dismantling consists of two sections. The module is cut and disassembled by robotic arms. Position confirmation through image and coordinate positioning for automatic cutting and dismantling work.

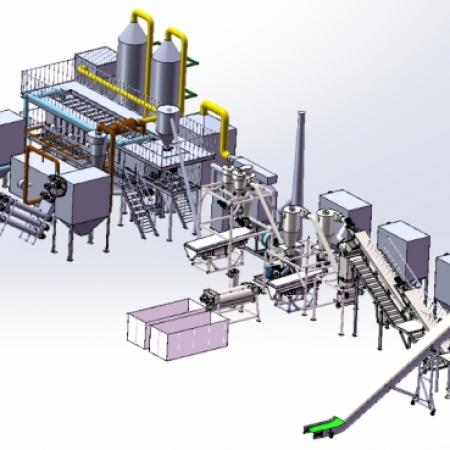

This process is mainly aimed at the layout of the dismantling process of the power battery module, and the layout is used for the cascade utilization of the power battery;

This process is based on the design of a power lithium battery module, and is finally disassembled into:

● Monolithic module – tested, directly cascade utilized

● Single battery – tested, direct cascade utilization

● End-of-life batteries – shredded and recycled

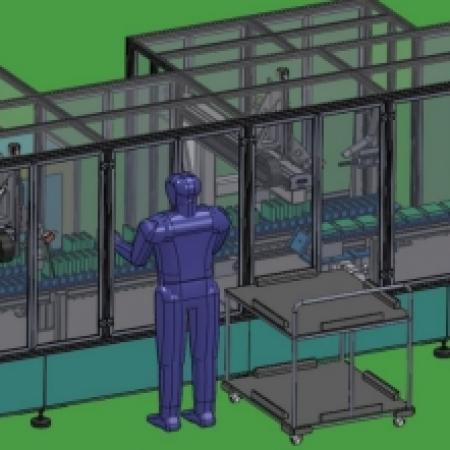

The process layout adopts a modular assembly line layout, and the entire dismantling action is completed in the mode of semi-automation and manual collaboration.

Battery Module Dismantling Process

1). Hoisting: the module to be dismantled is hoisted onto the double-speed chain of module dismantling.

2). Cut FPC: cut the FPC manually.

3). Cache: Cache station.

4). Break the rivets: drill the rivets of the module through an electric drill to loosen the rivets fixed on the side plate of the module (the station is equipped with jacking rotation, and the module can be clamped through the module clamping mechanism before drilling after rotation in place).

5). Dismantling the side plate and end plate: manually place the disassembled module side plate and end plate in the designated position.

6). Dismantle the cell: manually remove the pad attached to the cell.

7). Cutting the connecting piece: the manually assisted cutting mechanism cuts the connecting piece on the module.

8). Pick up the cells: manually transport the individual cells to the module sorting conveyor line.

Our engineering team can walk you through the design process and help you choose the suitable integrated solution for the scrapped lithium battery that best fits your needs and at a price that will fit your budget. Please contact us for more information and obtain quotation concerning your request.

jccms

jccms